BonnyView and ALLU the perfect partners

When mine and quarrying veteran Len Hardy decided he needed two “big” new buckets for his of Bonnyview Quarries business in NSW, he knew exactly what brand he wanted and where to turn to when he wanted to buy them.

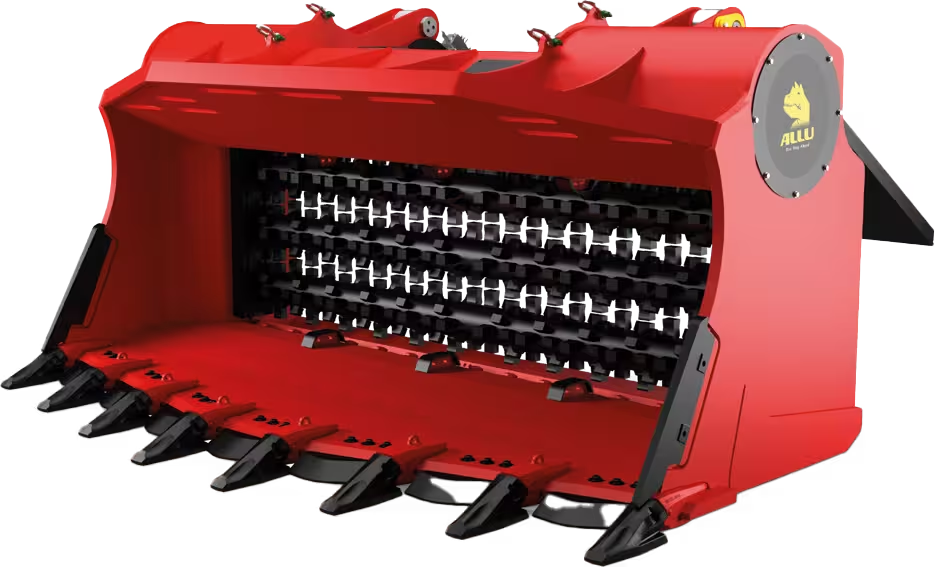

Having used a number of smaller ALLU buckets on his excavators over the years, Len had his eyes on a pair of ALLU DH4-23 XHD25 screening buckets to take on the bigger jobs and provide additional versatility to his operation, which supplies customers right across NSW.

Built by Finnish private limited company ALLU Finland Oy, the ALLU screen crushers are highly versatile and the ideal tool for creating material such as road base and building materials.

According to Len, they are the perfect fit for his business.

“They are the best constructed buckets for the applications we use them for. They are really well engineered and provide a very reliable performance,” he said.

“The two new buckets we acquired are performing really well and we couldn’t be happier.”

Len is just as high in his praise for local ALLU support distributors in Australia, with whom he has had a lengthy relationship.

“RDW group are a very, very, good company to deal with. They are great suppliers and will always come up with what you want,” he recently told Australian Mining Review.

RDW group has been the Australian importer and distributor for ALLU for around four years. distributing the product through a nation wide network, servicing major infrastructure projects including water and gas , however, the versatile ALLU system is quickly making inroads with civil and composting contractors.

Sales Area Manager in Rockbreakers Queensland, Craig Einam, said ALLU bucket applications and installations continue to grow and develop each year.

The versatility of the buckets to be fitted to 5T – 80T excavators and larger style loaders makes them particular popular with quarry operators like Len, while the smaller buckets are also effective on skid steer loaders.

About the ALLU Screener Crusher

With the ALLU Screener Crushers you can screen, crush, pulverise, aerate, blend, mix, separate, feed and load materials all in one stage.

The versatile accessory can process many types of material such as topsoil, black top and dirt, excavated and waste soil, contaminated soil, clay, peat, bark, compost, biowaste, demolition waste, construction waste, milled asphalt, glass, coal, oil shale, limestone and several other materials.

The versatility of the highly efficient ALLU screening buckets can also mean big savings for their users as they no longer need to bring both a wheel loader/excavator and a crusher on site. Instead, this is a bucket which screens, crushes, pulverises, aerates, blends, mixes, separates, feeds and loads materials.

ALLU has the widest range of screening buckets and screener light crushers on the market. The units fit for almost any base machine size starting from the most compact ALLU DL Series to the massive ALLU M Series that will fit up to 160 tonnes excavator.

The DH4-23 XHD25 screening buckets are part of the impressive ALLU Transformers range which are purpose built for efficient material processing by reducing the number of process steps needed and transforming waste into useable material.

Mining applications

Efficient material flow is a key issue in any mining operation, power plant, bulk harbour and bulk material or storage area.

ALLU Transformer Screener Buckets mounted on an excavator improve efficiency in material processing due to work speed and reach which results in almost double the processing capacity compared to a slow-moving wheel loader as a carrier.

With ALLU’s Screener technology, existing loaders and excavators can be converted into effective processing, sorting and screening equipment due to the ALLU Transformers ability to deliver a one-step screening and loading solution capable of handling all materials from wet soils to coal and softer rock materials.

This helps improve efficiencies through less chute blockages and also reduces the need for buffer storage areas and transportation of material heaps that are clogged due to moisture or contamination.

When looking at a project with a holistic approach given multiple equipment mobilisations, fuel costs and cost to process in low margin return Ore reclaiming projects etc.

ALLU Case studies have shown between $1.50-$2.50 per tonne savings in running costs in comparison to multiple unit processing configurations.

The ALLU Transformer M series of buckets for mining applications suit 50 to 160 tonne excavators and 30-90 tonne wheel loaders. To meet the specific needs of each application – a range of blade and drum sizes are available to provide fragment sizes of 50, 75, 100 and 150mm.

Dealer Network Servicing the country.

All the ALLU distributors are well known across Australia as suppliers of an extensive range of leading European and Australian manufactured excavator and skid steer attachments, such as those from ALLU.

They have a strong focus on ensuring the customers are using the right attachment for the task – ensuring it is not only safer, but also helps reduces downtime, lower operating and lifetime ownership costs and – most importantly – helps them reduce the cost per tonne of material moved.

When a full turn-key solution, integration or varied application for equipment is required, the network have it covered, engineering and project management resources have proven record of delivering innovative, high-quality and cost-effective solutions to optimise your operations.

Australian ALLU dealer network:

QLD Rockbreakers in QLD and NT:

rdw.com.au/qld-rock-breakers

Walkers Hammers in VIC:

walkershammers.com.au

Total Rockbreaking Solutions in WA:

totalrockbreaking.com.au