Screening Bucket for heavy-duty operations

Whether you’re on a large construction site or in a mining operation, the ALLU M-Series Screening Bucket helps you get the job done quickly and efficiently, and to reduce double handling of material. The M-Series Bucket is perfect for large-scale material processing and screening jobs, making tough tasks easy. It’s compatible with large excavators and wheel loaders.

ALLU M-Series is suitable for a wide range of applications in industries such as mining, and quarrying. It can be used for screening, crushing, mixing, and loading materials, among other tasks. By incorporating the M-Series into your operations, you can increase efficiency and productivity. ALLU M-Series Bucket can eliminate the need for material processing equipment and reduce the need for material double handling.

Meet environmental goals and regulations with the M-Series Bucket. On-site processing cuts down the need for transportation and separate processing, which means fewer emissions and resources.

Save on operational costs by integrating screening and loading into one efficient process. The ALLU M-Series Bucket reduces the need for additional machinery and manual labor. You get significant cost savings, as the bucket is built to last and you need to transport fewer materials.

M-SERIES FOR EXCAVATORS

M-Series Screening Bucket mounted on excavators is recommended because of work speed and reach, which results in almost double the processing capacity compared to a wheel loader as a carrier.

| | M 3-20 | M 3-25 |

| CARRIER | 50-70 t | 70-120 t |

| VOLUME | 2,82 – 3,86 m3 | 3,64 – 5,00 m3 |

| WEIGHT | 7000 – 8000 kg | 9000 – 11000kg |

| MAX. PRESSURE | 350 bar | 350 bar |

| OIL FLOW | 300-440 L/Min | 300-440 L/Min |

M-SERIES FOR WHEEL LOADERS

The M-Series mounted on wheel loaders are recommended when equipment mobility is one of the main criteria on the jobsite. Operations at harbours, power plants, and other bulk material storage areas, will benefit from bringing the machine to the material.

| M 3-32 | |

| CARRIER | 50-70 t |

| VOLUME | 4,60 m3 |

| WEIGHT | 10500 -13500 kg |

| CAPACITY | 350 t/h |

| MAX. PRESSURE | 350 Bar |

| OIL FLOW | 300-440 L/Min |

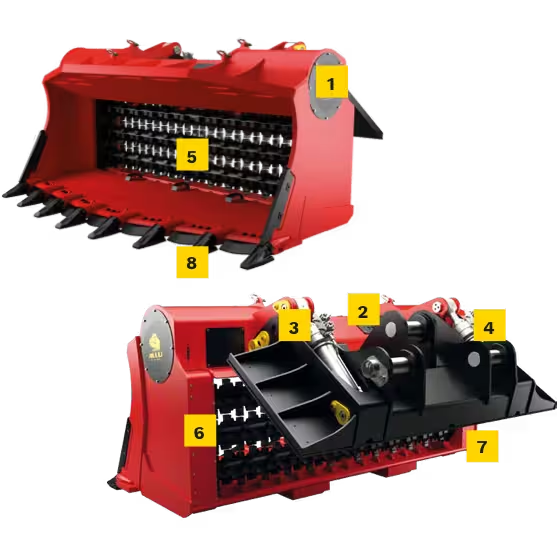

M-Series Structure

1. Two hydraulic motors

2. Power Control Valve

3. Pin mount adaptation and bushings

4. Rotating crushing drums

5. Patented rear-mounted bearing and drum construction

6. Heavy-duty chain drive

7. Changeable wear parts

Unique design for bulk and mining material handling

1. Two hydraulic motors

2. Power Control Valve

3. 100t Cylinder Force

4. Hydraulically operated hinged rear lid/adapter

5. Rotating crushing drums

6. Patented rear-mounted bearing and drum construction

7. Heavy-duty chain drive

8. Changeable wear parts

Book a free consultation

With the ALLU M-Series Screening Bucket, you can boost efficiency, save costs, and meet sustainability regulations. Don’t wait – get your job done easier with ALLU!

INTELLIGENT REPORTING

- Touch screen monitor inside cabin

- Assists the operator

- Hydraulics, parts temperature & productivity monitoring

- Mobile data uplink to service terminal available

- Operating time recording

- Monitoring of the equipment condition.

Didn’t find what you were looking for?

Get to know our other Screening Bucket products, and find the perfect one for you. If you need help finding the perfect option for you, please get in touch with us and we’ll guide you.