WHY CHOOSE ALLU SCREENING AND CRUSHING BUCKETS FOR QUARRYING?

PROCESS QUARRY MATERIALS RIGHT WHERE YOU NEED THEM.

The ALLU Transformer Series enhances quarrying operations by making material processing more efficient and cost-effective. ALLU helps you maximize productivity by combining screening, processing, and loading in a single, mobile step. This streamlined approach eliminates multiple machine requirements, reduces material handling, and enables processing right at the extraction point.

Whether handling limestone, soft minerals, or quarry by-products, the ALLU Transformer Series adapts to your specific requirements, delivering consistent results without the need for stationary plants or additional equipment.

Why ALLU is the perfect fit for your quarrying operation:

- Efficient Processing: Handle soft quarry materials with optimal throughput capacity, from limestone to soft minerals.

- Reliable Performance: Process damp or clumped materials without clogging, maintaining consistent operation in varying conditions.

- Quality Control: Screen and size materials in one step, ensuring product consistency while reducing handling costs.

- Flexible Output: Adjust material sizing to meet specific requirements, delivering products that match market demands.

Quarry Screening and Crushing Buckets

ALLU provides reliable solutions for all your material processing needs in quarrying. Our equipment ensures efficiency, reduced costs, and seamless handling of various materials on-site.

Material Processing Solutions for Quarrying Operations

ALLU’s screening and crushing buckets bring efficiency to quarrying operations, specializing in processing limestone and soft minerals. By optimizing material flow and reducing equipment needs, our attachments enhance operational flexibility while maximizing productivity at quarry sites.

Limestone Screening

Quarry operations need efficient solutions for processing limestone materials. ALLU’s DH Series screening buckets with TS/X75 blades are specifically engineered for limestone processing applications. The single-step screening process ensures consistent sizing while eliminating the need for stationary equipment. By processing materials on-site, ALLU buckets reduce operational costs while maintaining high productivity.

- Application: Limestone screening and processing

- Equipment: DH Series screening buckets

- Benefits: On-site processing, maintenance savings, operational flexibility

Quarry Site Remediation

Quarry remediation demands efficient solutions for processing leftover materials. The ALLU DH 3-17, equipped with TS35 standard blades, transforms site cleanup into a value-creating operation. Processing a full bucket in less than a minute, this attachment separates industrial-grade rock while converting fines into valuable construction materials.

- Application: Site remediation and material recovery

- Equipment: DH 3-17 TS35

- Benefits: Environmental compliance, material recovery, cost efficiency

Getting Started with ALLU for Your Quarry Needs

Take these simple steps to improve your quarry efficiency with ALLU:

- Expert Assessment: Let’s discuss your quarry operation’s specific challenges and explore efficient processing solutions together.

- Tailored Solution Design: Our specialists will analyze your requirements and recommend the optimal equipment configuration for your site.

- Seamless Implementation: From order to delivery, we ensure a smooth transition to enhance your quarry’s processing capabilities.

- Ongoing Partnership: Benefit from our comprehensive support network, ensuring your operation maintains peak performance.

ALLU’s screening and crushing buckets enhance quarry operations by streamlining material processing and reducing operational costs. Transform your site’s efficiency with solutions designed for soft mineral processing and environmental compliance. Take the first step toward optimizing your quarry’s performance with ALLU.

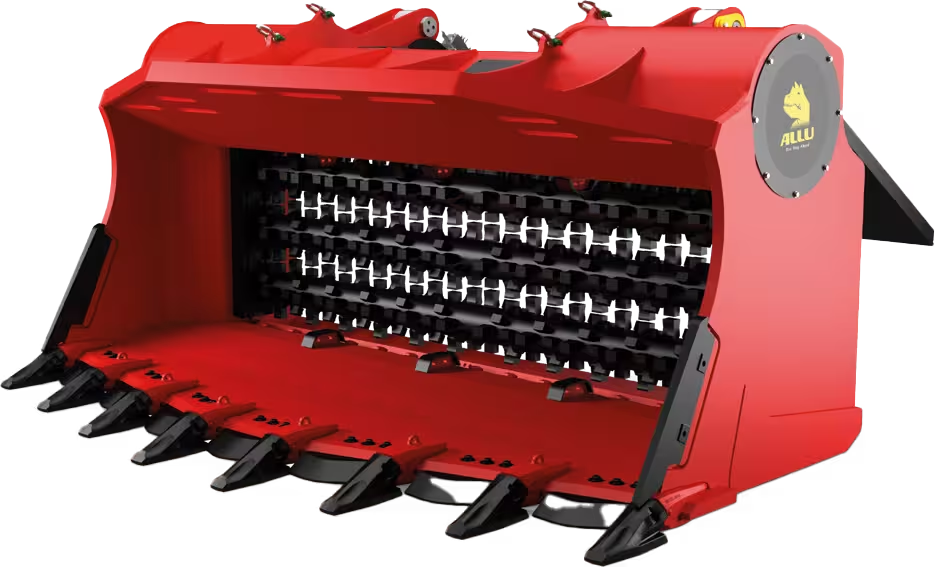

M-Series and DH-Series Features

ALLU Transformer M-Series and DH-Series Screening Buckets are engineered for demanding quarry applications. These heavy-duty attachments excel in soft mineral processing and material recovery, offering robust solutions for high-volume operations. Whether mounted on excavators or wheel loaders, both series deliver efficient screening and processing in one mobile solution.

Key capabilities of M-Series and DH-Series:

- High-Volume Processing – Handle substantial material quantities while maintaining consistent output quality.

- Mobile Operation – Process materials where needed, eliminating transport to stationary plants.

- Versatile Mounting – Compatible with large excavators and wheel loaders for operational flexibility.

- Reliable Performance – Maintain productivity across varying material conditions and processing requirements.

CUSTOMER STORIES

Can’t find the right solution? Explore our other applications, from mining to composting.

- Demolition

- Composting

- Construction

- Aerating

- Utility and road works

- Pipeline padding

- Solar padding

- Asphalt recycling

- Waste rock handling

- Concrete recycling

- Topsoil screening

- Waste processing

Book a free consultation

With the ALLU M-Series and DH-series Screening Crushing Bucket, you’ll ensure smoother everyday operations while converting raw materials into more valuable forms.

Don’t wait – get your job done easier with ALLU!