WHY CHOOSE ALLU SCREENING AND CRUSHING BUCKETS FOR MINING?

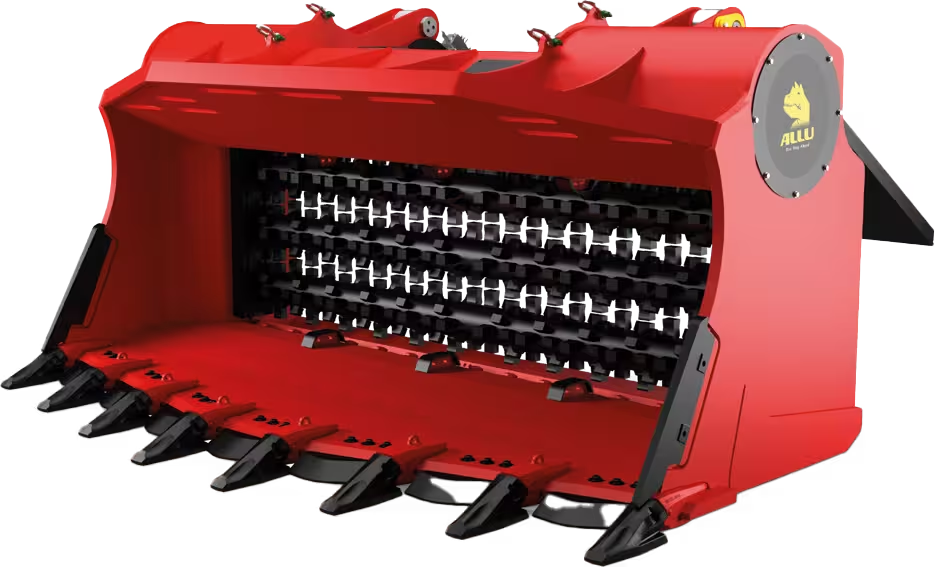

MORE THAN JUST A BUCKET FOR HEAVY-DUTY MACHINES AND OPERATIONS.

The ALLU Transformer M-Series is designed to transform the way mining operations handle material processing, making it faster, more efficient, and cost-effective. ALLU help you save time and resources by combining screening, crushing, and loading in a single, mobile step. This eliminates the need for multiple machines, reduces double handling, and allows you to process materials directly at the source.

Whether it’s frozen iron ore, soft rock, or gold ore tailings, the Transformer M-Series adapts to the specific needs of your operation, delivering reliable results without the need for stationary plants or additional equipment.

Why ALLU M-Series is the perfect fit for your mining operation:

- High material throughput: Handle large volumes of hard or abrasive materials like iron ore and coal with high processing capacity.

- Tough material handling: Process sticky, wet, or clumped materials (such as coal slurry or frozen ore) without clogging or equipment failure.

- Separation efficiency: Separate waste rock from valuable ore in one step, increasing material purity and reducing transport costs.

- Customizable output: Tailor material size to exact specifications (50mm, 75mm, 100mm, or 150mm), ensuring consistency in product quality.

Mining Screening and Crushing Buckets

ALLU provides reliable solutions for all your material processing needs in mining. Our equipment ensures efficiency, reduced costs, and seamless handling of various materials on-site.

Material Processing Solutions for Mining Operations

ALLU’s screening and crushing buckets are built to handle a wide range of materials in mining, from coal to gold ore and beyond. By improving material flow and eliminating the need for multiple machines, our equipment enhances operational flexibility and optimizes output for mining operations.

Coal Crushing and Screening

Coal mining operations require efficient equipment to process large volumes of material. ALLU’s DH 3-23 and M 3-20/M 3-25 screening buckets are specially designed to crush and screen coal and coal rock. The one-step process of crushing and screening ensures consistency in material size, reducing double-handling and waste. With X55 and X75 blades, ALLU buckets help increase coal value, making it easier to transport and use.

- Application: Coal crushing and screening

- Screening Buckets: DH and M-Series

- Benefits: Efficient, one-step process, reduces double-handling, low maintenance costs

Gold Ore Processing

For gold mining, ALLU’s DH and M-Series screening buckets excel in processing tailings and extracting valuable material. These buckets can handle wet and sticky materials, maximizing the utilization of gold ore by processing waste materials and improving yield. The high wear resistance of the X75 and TS S50 blades ensures that gold mining operations can handle tough materials with ease, delivering a higher-quality end product and increased profitability.

- Application: Gold ore processing

- Machine Compatibility: DH and M-Series

- Benefits: Maximizes material utilization, handles sticky and wet materials

Getting Started with ALLU for Your Mining Needs

Take these simple steps to improve your mining efficiency with ALLU:

- Schedule a free consultation: Our team will connect with you to understand your mining requirements and explore the best solutions.

- Receive customized recommendations: We’ll provide expert advice tailored to your operation and offer a no-obligation quote.

- Proceed with confidence: Once you’ve made your decision, we’ll handle the order processing and ensure timely delivery.

- Count on global support: After your purchase, our international support network will be available to assist you whenever necessary.

ALLU’s M-Series and DH-Series screening and crushing buckets are designed to improve the efficiency of your mining operations, reduce downtime, and enhance productivity. Begin today and see how ALLU can help elevate your mining processes to a higher standard.

M-Series and DH-Series Features

ALLU Transformer M-Series and DH-Series Screening and Crushing Buckets are built for heavy-duty material handling in mining and quarrying. From processing iron ore and coal to managing gold ore and soft rock, these buckets are designed to tackle challenging tasks with ease. Mounted on excavators or loaders, they screen, crush, and load materials efficiently in a single, seamless operation.

The screening and crushing buckets specialize in:

- Screening – Suitable for all types of materials, ensuring efficient separation of unwanted particles to meet specific size requirements.

- Scalping – Effectively removes larger materials and oversize particles, enhancing the quality of the processed material.

- Re-crushing – Designed to handle frozen or clumped materials, breaking them down for easy transport and further processing.

- Crushing – Ideal for soft and brittle materials, providing consistent and efficient reduction to the desired size for further processing.

CUSTOMER STORIES

Can’t find the right solution? Explore our other applications, from mining to composting.

- Demolition

- Composting

- Construction

- Aerating

- Utility and road works

- Pipeline padding

- Solar padding

- Asphalt recycling

- Waste rock handling

- Concrete recycling

- Topsoil screening

- Waste processing

Book a free consultation

With the ALLU M-Series and DH-series Screening Crushing Bucket, you’ll ensure smoother everyday operations while converting raw materials into more valuable forms.

Don’t wait – get your job done easier with ALLU!