ALLU Group will have its experts on hand in Central Hall booth #C20326 at ConExpo-Con/AGG 2020, March 10-14, 2020, in Las Vegas. Visitors will learn how ALLU Transformer screener crusher attachments and the company’s new TS blade structure will transform unusable dirt, construction waste and green waste into valuable material, ultimately transforming the way contractors and producers work.

More Fragment Sizes with Advanced ALLU TS Blade Structure

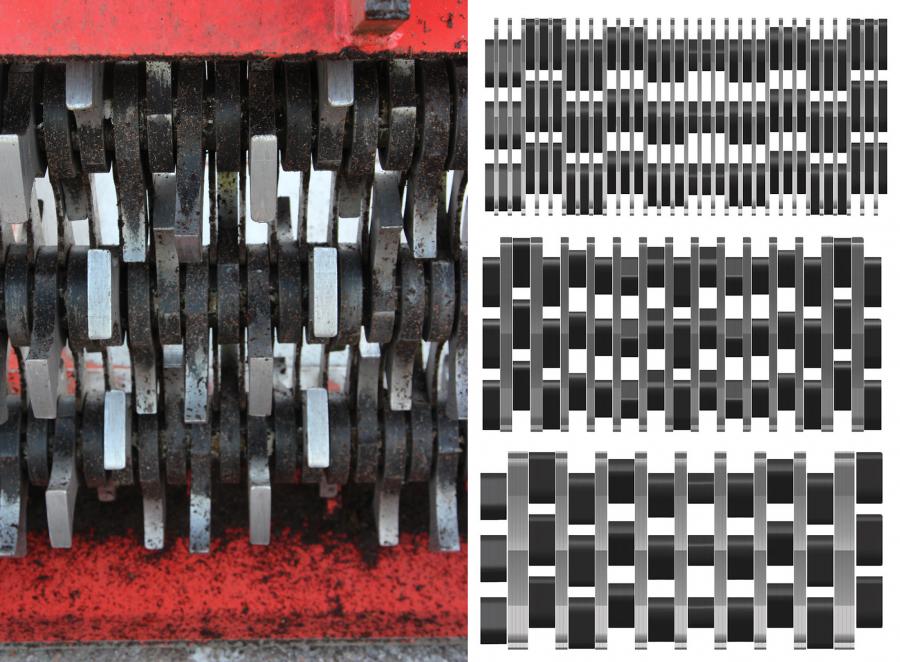

ALLU’s TS blades are an advanced development for the attachment screener/crusher market. With the ALLU TS drum, screening blades spin between screening combs. The end product size is defined by the space between the combs. And now an updated ALLU TS blade structure has been developed that delivers increased levels of versatility, efficiency and productivity, according to the manufacturer.

ALLU TS drums are available with two different blade types: standard blades for screening and axe blades for crushing or shredding. Fragment size is based on screening comb distance, which is easy to change between screening jobs for more versatile processing. The latest development to the ALLU TS assembly enables a greater number of fragment sizes from same unit. The single blade setup positions two or three blades in a single position, with a screening comb between every blade. Operators can now double or even triple the blades and combs, allowing up to three times more fragment size variations from 8mm up to 105mm. With this new ability, ALLU now offers the widest range of fragment variations on the market.

What is the ALLU Transformer?

ALLU Transformer attachments work with wheel loaders, excavators, skid steers and backhoes to screen, crush, pulverize, aerate, blend, mix, separate, feed and load materials all in one stage — increasing an operation’s efficiency and profitability. The unit is designed to process wet or dry materials quickly and efficiently, reducing cycle times and resulting in increased production and substantial savings on operating costs.