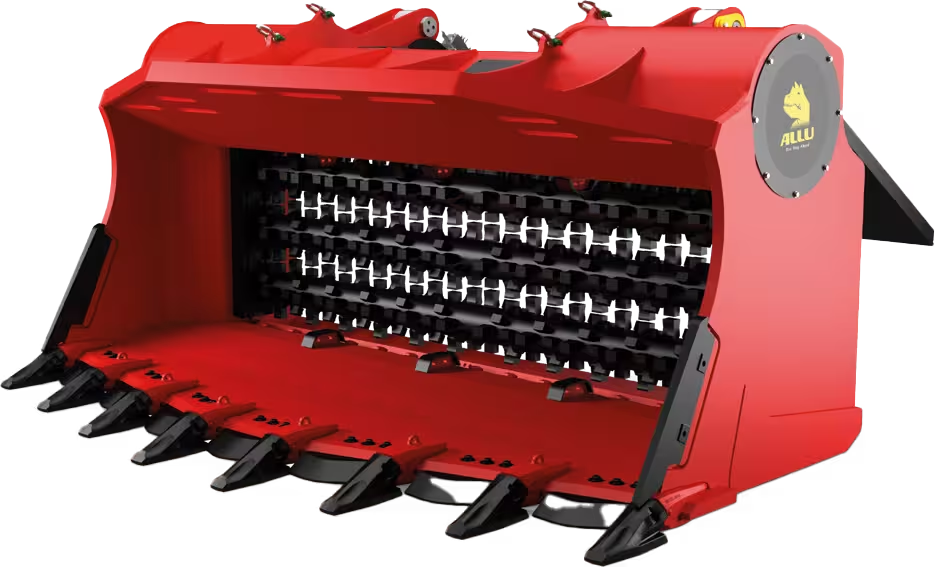

DESIGNED FOR MINI EXCAVATORS

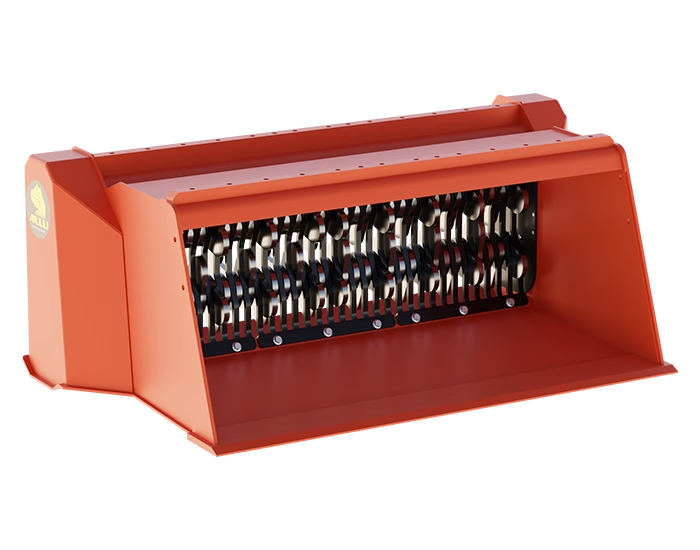

The ALLU DC-Series Screening Bucket is the perfect tool for jobs of all sizes, particularly well-suited for mini excavators. It screens, separates, and crushes materials such as soil, sand, compost, and biomass with ease.

This compact and agile bucket is designed to improve your on-site efficiency by simplifying processes, saving time, and reducing the need for additional equipment.

With the DC-Series, you can streamline your operations, save money, and increase profits. Our experts are here to help you find the perfect solution for your material processing needs.

With DC-Series you can:

- Screen, and mix materials in one operation and save money: Improve cost-efficiency by reducing the need for multiple pieces of equipment.

- Handle wet, sticky, or compacted materials smoothly: Its advanced features allow for more consistent processing by preventing blockages and maintaining a continuous workflow. This will help reduce downtime and ensure more operations can be completed on-site.

- Enhance your productivity by reducing waste: This bucket reduces waste by enabling on-site material processing, minimizing the need for material transportation to and from landfills, and allowing for the reuse of processed materials.

DC-Series models

Our DC-Series Screening Bucket comes in three sizes. The first number in the model name is the number of drums, and the last number is the width of the bucket e.g. 08 means 800mm.

DC 2-04

DC 2-08

DC 2-12

Technical Specifications

| Excavator | 2 – 4 t |

| Volume | 0.11 m3 |

| Max. Pressure | 200 bar |

| Oil flow | 15 – 30 l/min |

| Weight | 170 kg |

| Excavator | 4 – 6 t |

| Volume | 0.23 m3 |

| Max. Pressure | 200 bar |

| Oil flow | 20 – 40 l/min |

| Weight | 270 kg |

| Excavator | 5 – 10 t |

| Wheel loader | 2 – 4 t |

| Volume | 0.42 m3 |

| Max. Pressure | 200 bar |

| Oil flow | 40 – 80 l/min |

| Weight | 415 kg |

How to get started?

Follow these easy steps:

- Request a free consultation: Our experts will contact you to discuss your specific needs.

- Get personalized recommendations: We’ll provide tailored advice and a no-obligation quote.

- Move forward with confidence: Once you decide, we’ll process your order and arrange delivery.

- Have global professional support: After your purchase, we make sure that you’ll have support whenever you need it.

With the ALLU DL-Series, you can streamline your operations, save money, reduce environmental impact, and increase profits. Don’t wait – get your job done easier with ALLU!

BETTER FOR YOU

BETTER FOR THE ENVIRONMENT

DC-Series features

Strong and reliable – Motors are placed inside the frame to avoid any damage from the outside. The lubrication inside the chain boxes ensures a long transmission lifetime.

Efficient – Produces homogenous end product and works with wet materials. Quick and easy to maintain with a self-cleaning design.

Versatile – Suitable for mini excavators and handles many different materials, including wet ones.

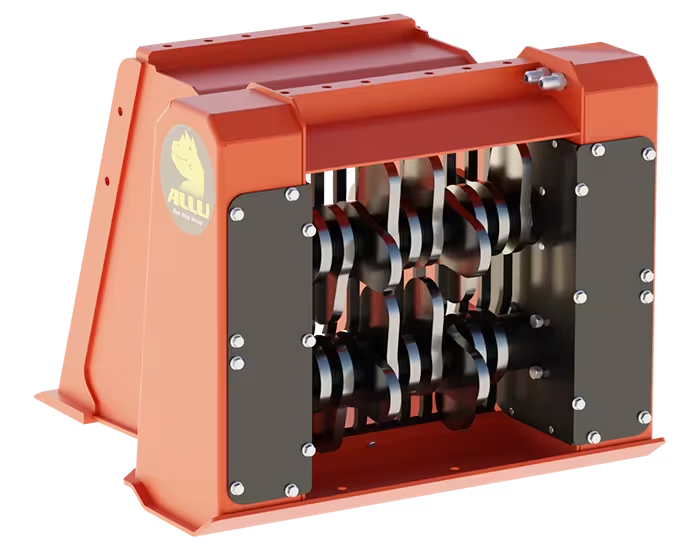

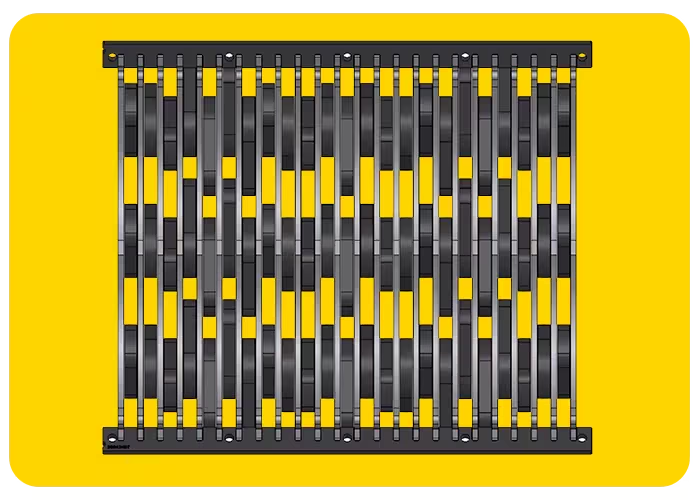

TS STRUCTURE

SELF-CLEANING DESIGN

TWO-WAY ROTATION

The drums can be rotated in both directions to ease the material handling. The bucket can handle screening of difficult materials such as wet, tough, or soil that has hardened lumps in it.

SELF-CLEANING TS STRUCTURE

The patented ALLU TS Blades have a Self-Cleaning Design, which allows the best possible capacity even with wet materials.

Request a free consultation

With the DC-Series Screening Bucket, you can streamline your operations, save money, and increase profits. Our experts are here to help you find the perfect solution for your material processing needs.

Don’t wait – get your job done faster with ALLU!

Main Application Areas

- Aerating

- Screening

- Composting

- Pipeline padding

- Waste material handling

- Landscaping

ROBUST – RELIABLE – ADVANCED

ALLU Tracker

Keep your equipment safe and monitor their use with the ALLU data tracker.

- Easily mounted data tracking devices in an IP69k design. Battle-proven and tested under the harshest of circumstances.

- Monitor running hours based on motion.

- Worldwide GSM network coverage with LTE and 2G fallback. The data logging feature ensures data is stored if networks are unavailable.

- Devices can always be located with built-in GPS or network triangulation positioning.

- Manage online from anywhere, all hardware is managed online on the ALLU Data Portal.

ALLU Tracker has a long battery life of up to 5 years. Due to its small size (68 x 68 x 25 mm) and easy mounting with magnet, it doesn’t interfere with the structural integrity of the ALLU products.

Didn’t find what you were looking for?

Get to know our other Screening Bucket products, and find the perfect one for you. If you need help finding the perfect option for you, please get in touch with us and we’ll guide you.