Help & FAQs

Explore How-To Videos and FAQs

Welcome to your resource hub for ALLU operational excellence. Here, you’ll find a collection of how-to videos and frequently asked questions designed to enhance your understanding and use of ALLU products.

From step-by-step guides on getting the most out of your equipment to troubleshooting common issues, our how-to videos provide practical, easy-to-follow instructions. Dive into our FAQs to answer your queries quickly, ensuring your projects continue smoothly with minimal downtime.

Start exploring today to maximize your productivity with ALLU!

How-to Videos

Correct use of ALLU Screening Bucket

In order to achieve the best results and ensure the longevity of your ALLU Screening Bucket, it is essential to use the equipment correctly.

Watch the video to learn how to screen and crush effectively, how to properly fill the bucket, the optimal working angle, and what practices to avoid with the bucket.

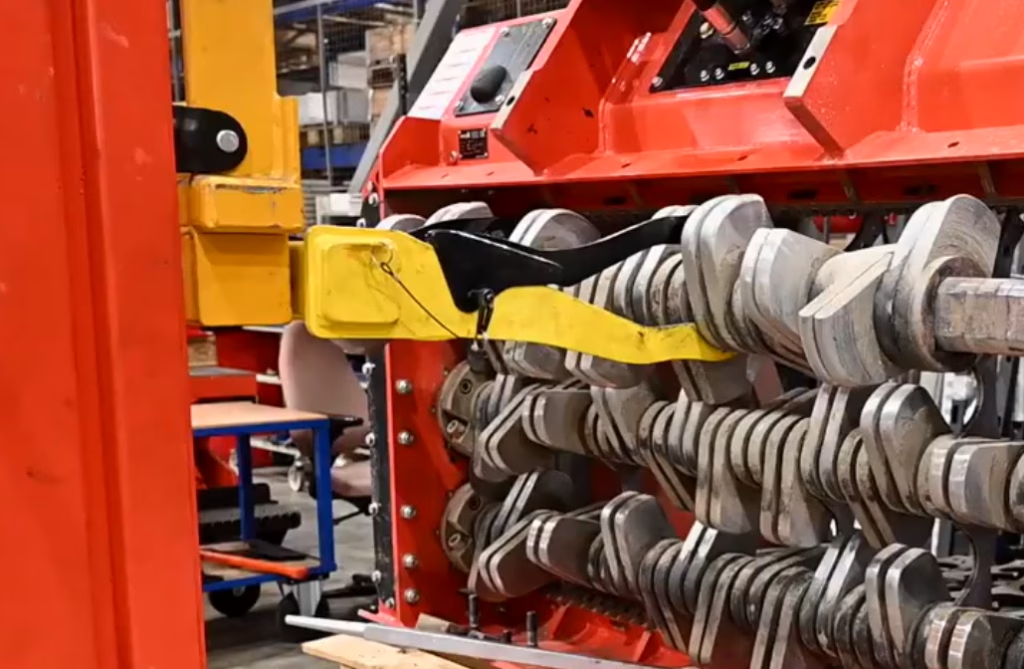

How to replace X-Drum blade

Regular maintenance is crucial for ensuring the efficiency and longevity of your ALLU equipment. In this video, we’ll guide you through each step of the blade replacement process on an X-Drum.

Using authentic parts not only guarantees a perfect fit but also upholds the performance standards you expect from ALLU products. Follow along as we demonstrate the correct procedure to ensure your equipment continues to operate at its best.

Changing the fragment size on TS-Drums

The patented ALLU Top Screen design enables two different fragment sizes within the same unit. The fragment size is based on the screen comb spacing. There’s no need to remove the drums to change the fragment size. It is a quick and easy way to switch from one screen application to the next.

Available blade sizes and the doubling:

8 mm / 16 mm

16 mm / 32 mm

25 mm / 50 mm

35 mm / 70 mm

How to remove a drum on D-Series

The animated video shows how to correctly remove a drum from the ALLU D-Series Screening Bucket. Follow the step-by-step guide and remove the drums safely.

Variable Drum replacement

The video shows how to remove and replace a Variable Drum on an ALLU Screening Bucket correctly.

FAQs

Here you can find the Frequently Asked Questions about ALLU Screening Buckets. See the questions and learn new tips for getting the best results from your screening bucket.

When do I need to change the blades on my screening bucket?

Depending on the material and the operating hours, the blades on ALLU Screening Buckets need to be replaced to maintain the quality of the work. A good rule of thumb is that when you’re not happy with the end result – it’s time to check the blades. Lowered processing capacity or changes in the fragment size are usually caused by wear.

The wear on TS-blades can be seen as a shortening of the blade. X- and XHD-blades start to lose their angular shape and become rounded on the edges.

Do I need any special tools when changing drums and blades?

Special tools are required to safely change the drums and blades on a screening bucket. You need an extractor tool for the blades, a bearing unit tool, and a manual cotter press, which are all delivered with the bucket. Impact drill compatible cotter press is available as an accessory (SDS Max head).

We can also provide you with tools for lifting drums safely and to make TS blade installation easier. Always secure the drums to an appropriate hoisting device when moving them to prevent them from falling.

Can I change between different drum types using the same screening bucket?

Yes, different drum types in ALLU buckets are interchangeable and can be replaced without structural changes in the frame.

Please contact ALLU Support for more information.

Also check out ALLU Variable Drum for the ultimate flexibility in blade and drum changes.

How long is the warranty period for my screening bucket?

The standard warranty period for ALLU products is 12 months / 1000 carrier hours. An extended two-year warranty is available as an option for DL- & D-Series.

Spare parts have a 6-month warranty period from the date of installation.

What can I crush with the ALLU Screening Bucket?

There is an easy way to check this – If you can break or crush the material with a regular household hammer, you can crush it with ALLU. Materials like limestone, leca blocks, hardened concrete sludge, and other brittle materials are suitable to crush with a screening bucket.

For crushing hard materials like natural rock, we recommend using the ALLU Crusher.

What are the hydraulic requirements for ALLU bucket?

In general, all ALLU buckets require two-way hydraulics (shear circuit) to function as designed.

D-Series:

- Two-way hydraulics & drain line back to tank

- Max. pressure 300 bar, flow 70-400 lpm

DL-Series:

- Two-way hydraulics, no need for a drain line

- Max. pressure 200 bar, flow 60-90 lpm

DC-Series:

- Two-way hydraulics, no need for a drain line

- Max. pressure 200 bar, flow 15-40 lpm

What does the power control valve do in the D-Series?

The power control valve in the D-Series plays a crucial role in protecting the bucket from excess oil flow and pressure. This valve ensures that it is not necessary to manually limit the maximum pressure in the device circuit of the base machine.

All D-Series Screening Buckets are equipped with a power control valve, safeguarding the Transformer against hydraulic overload. The valve automatically begins to regulate the motor’s pressure difference when it exceeds 280 bar and controls the hydraulic flow once it surpasses the model-specific maximum value. This feature is integral to maintaining optimal performance and longevity of your equipment.

Do I need a drain line for my machine?

ALLU D-Series Buckets require a drain line to protect the hydraulic motor. When the carrier does not have a dedicated drain line, the Drain Line Eliminator™ (DLE) is available as an optional solution.

ALLU D-Series Buckets are equipped with gerotor (orbital) hydraulic motors. These motors generate internal leakage that must be returned safely to the hydraulic tank via a dedicated leakage return, commonly known as a case drain or leak line. The drain line ensures the leakage oil flows back to tank at very low pressure, preventing unwanted pressure build-up inside the motor housing and protecting the motor from damage.

How often do the bearings need to be greased?

In the D-Series, bearings must be greased every 40 hours, or once a week.

Recommended bearing lubricants’ NLGI grade:

Operating temperature:

- Below 0°C –> 0

- 0-25°C –> 1

- Over 25°C –> 2

ALLU Support

Our global team is on hand to offer all the help you need. When it comes to getting the most out of your equipment and spare parts, we’re just a phone call or email away.

Fill out the form below or contact us directly for your support query. Please state your ALLU machine’s model and serial number in your message so we can find the correct parts or instructions fast for you.

Contact info

support@allu.net

Call ALLU Support

(GMT+2, 8am – 4pm)

+358 40 840 7400

North & South America Support

(Eastern time, 8am – 8pm)

+ 1-201-310-3282