ALLU is delighted to launch the NEW ALLU TRANSFORMER DC Series for the Chinese market. ALLU opened its new Chinese manufacturing plan in 2021, after listening to the needs of customers. It was clear ALLU needed a local facility to grow and support our Chinese customers. Investing in a local manufacturing facility has enabled ALLU to make products tailored to the local market requirements.

Operations Director for China Pierre Bujes says: ALLU have heavily invested in China and listened to our customers in China. Introducing the new DC Series, which ALLU have tailored just for the Chinese market this will strengthen our support to our customers and operational presence, to help grow the region whilst being competitive in the local market”

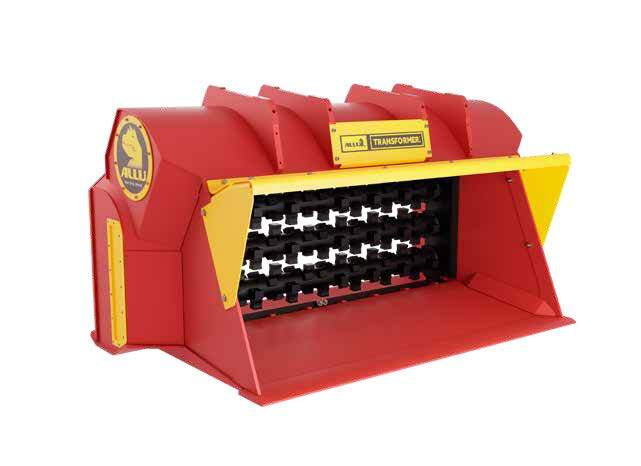

The ALLU Transformer DC Series are reliable screening attachments for a variety of screening, crushing, mixing, and aerating applications. All models are equipped with two hydraulic motors for maximum processing power. The attachments have reinforced

sides, making the bucket robust and durable even in demanding environments and with demanding materials.

The main areas of application for the ALLU TRANSFORMER DC Series are:

- Waste material handling & processing

- Compost mixing and aerating

- Pipeline backfilling/padding

- Stabilising clay

- Cable backfill

- Environmental remediation

- Soil & gravel screening

The ALLU TRANSFORMER DC Series offers two different blade options. Equipped with TS blades, the ALLU Transformer DC Series are perfect for applications that require screening, separation, and aeration. The TS blades rotate between the screening combs, and the final fragment size is 25-50mm. This structure is unique in that the fragment size of the final product can be changed by repositioning the screening combs. This allows you to get two fragment size variations with the same ALLU TRANSFORMER DC SERIES at no extra cost.

Equipped with X-blades, the ALLU TRANSFORMER DC SERIES attachments are perfect for applications requiring stabilization, mixing, aeration and crushing. The structure is clog-proof and the capacity remains superb even with wet materials. Thanks to the design, the ALLU TRANSFORMER DC SERIES with X-blades are well suited for even the most demanding mixing and pulverizing tasks.

ALLU is delighted to introduce Daniel, the Production Supervisor for China. He will be leading ALLU China production of the new DC series. Daniel started his career over 20 years ago and has worked for a few different European companies. Daniel has managed production in factories and for various organisations and has experience of growing the Chinese market.

ALLU is delighted to introduce Daniel, the Production Supervisor for China. He will be leading ALLU China production of the new DC series. Daniel started his career over 20 years ago and has worked for a few different European companies. Daniel has managed production in factories and for various organisations and has experience of growing the Chinese market.