Late in 1985, in Finland, ALLU’s story began with a simple belief: materials shouldn’t have to travel far to become useful again. The company started out focused on environmental technology- and kept that “make it smarter, make it practical” mindset as it grew into a family-owned, global attachment specialist.

From the very beginning, ALLU was built around engineering expertise, close customer collaboration, and a willingness to challenge traditional methods. Innovation was not treated as a separate function, but as a mindset embedded in everyday work. This approach laid the foundation for a company that would consistently stay one step ahead of industry needs.

A Timeline Defined by Practical Innovation

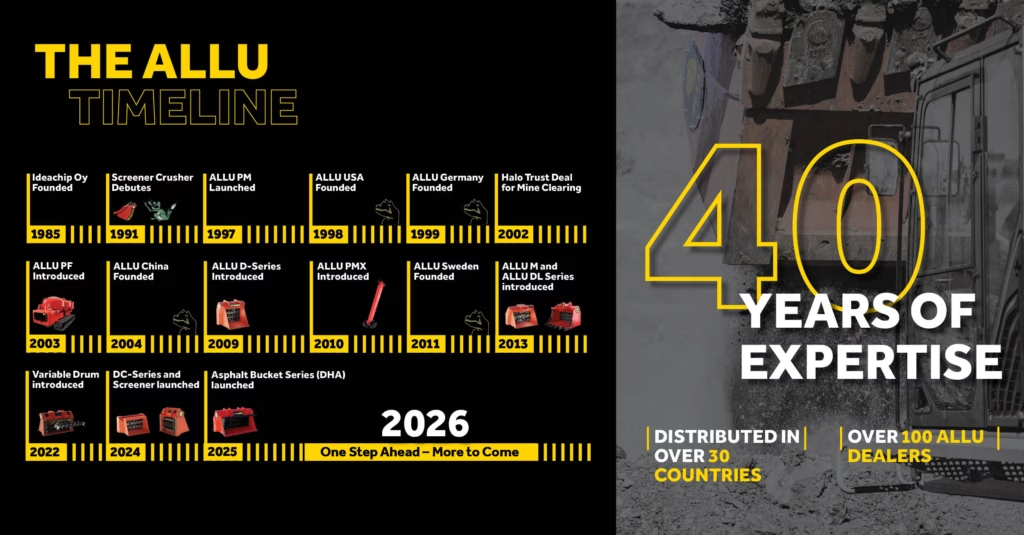

A major milestone came in 1991, when ALLU introduced the world’s first excavator-attached screening and crushing bucket. By adapting technology traditionally used in large stationary plants into a compact, mobile attachment, ALLU fundamentally changed what a single machine could achieve on a jobsite. Contractors could now screen and crush materials directly at the source, saving time, reducing transport costs, and improving efficiency.

Innovation continued throughout the following decades. The launch of the ALLU Power Mixer (PM) in 1997 expanded the possibilities of attachment-based processing, followed by the Pressure Feeder (PF) in 2003. The 2000s and 2010s saw significant product development and international growth, including the introduction of the D-Series, M-Series, DL-Series, and later the DC-Series screening buckets.

In recent years, ALLU has continued to respond to evolving industry demands. The Variable Drum concept, launched in 2022, increased flexibility in material processing, followed by new screening solutions in 2024 and the introduction of the ALLU Asphalt Screening Bucket in 2025 — designed specifically for cold-milled and reclaimed asphalt (RAP).

Values That Guide the Journey

At the core of ALLU’s success are values that have remained consistent for four decades: practical innovation, customer-driven development, and responsibility. ALLU solutions are designed to reduce waste, minimize unnecessary transport, and turn materials previously considered unusable into valuable resources.

Equally important is the people behind the technology. Long-term commitment, deep expertise, and close relationships with customers and dealers worldwide have shaped a culture where listening leads to innovation. As Peter Grönholm, CEO of ALLU Finland, states:

“Forty years of innovation isn’t about chasing ‘new’. It’s about making work simpler and more profitable where the material actually is.”

Looking Ahead

Fast forward to today, ALLU is still family-owned, and operating globally through more than 100 local dealers across 50+ countries. ALLU has daughter companies in the USA, Germany, Sweden and China. As ALLU celebrates its 40th anniversary in 2026, the focus remains firmly on the future, continuing to develop smarter, more efficient material processing solutions that help customers work better.

One Step Ahead. More to Come.