EFFICIENT SOLUTIONS FOR ASPHALT RECYCLING AND PROCESSING

WHY CHOOSE ALLU SCREENING BUCKETS?

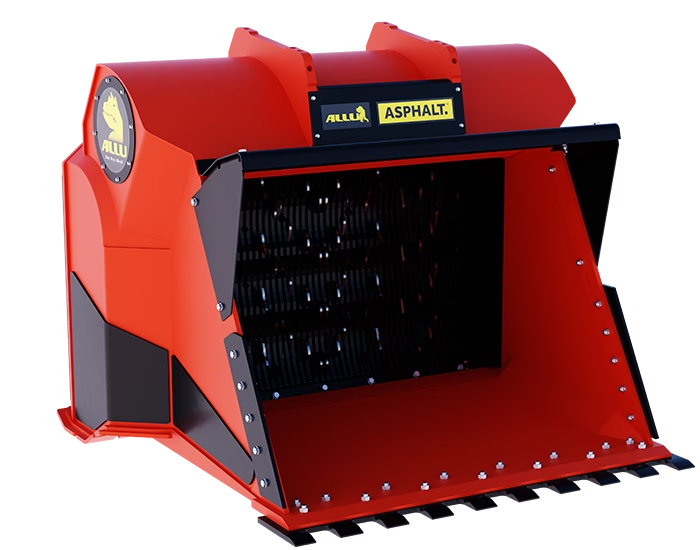

The ALLU Screening Bucket brings new efficiency to asphalt recycling, optimizing RAP processing and reducing costs. ALLU combines screening, crushing, and loading in one mobile operation – a practical solution that eliminates the need for multiple machines. Process materials right where they’re milled, turning waste asphalt into valuable RAP material on the spot.

Whether you’re handling cold-milled asphalt, large chunks, or sticky RAP material, the ALLU Asphalt Bucket handles each material type effectively, delivering consistent results without stationary processing plants. Pre-crush larger pieces, screen to size, and prepare material for immediate reuse – all with one attachment.

Why ALLU is the perfect fit for your asphalt processing:

- Efficient material handling: Process cold milled and chunk asphalt effectively – even when material is wet or sticky

- From waste to reusable material: Transform reclaimed asphalt into sized material that meets production standards

- Versatile applications: Handle everything from road planings to larger asphalt pieces in varying conditions

- One-step solution: Screen, crush, and prepare material for reuse in a single operation right where you need it

- Adaptable processing: Switch between different drums to match your material requirements – from screening to crushing

This Contractor Changed How They Process Asphalt

- Transform asphalt planings on-site with DS 3-23 and DH 4-17 buckets

- Process wet material that clogs conventional screeners

- Adapt to any job size – from small contracts to major projects

Screening and Crushing Buckets for Asphalt

ALLU makes asphalt processing work smarter. Whether you’re handling road planings or larger chunks, our equipment brings reliable processing power to your site, cutting costs while maintaining material quality.

Material Processing Solutions for Asphalt Recycling

ALLU’s screening buckets transform asphalt waste into valuable road materials. From milled asphalt to demolition material, our attachments process everything on-site, cutting costs while creating material that meets production specifications.

Asphalt Quality Control – Milled Material

Milled asphalt from road maintenance and reconstruction can be reused in new asphalt production, reducing the need for virgin materials while maintaining quality standards. Quality control is crucial as oversized material and lumps must be screened before feeding into the asphalt plant. The ALLU DN 3-12 with TS 25 drums ensures precise screening, replacing traditional static plants with mobile efficiency.

- Application: Asphalt quality control processing

- Screening Buckets: DN-Series with TS 25 drums

- Benefits: Mobile quality control at asphalt plant, efficient screening of oversized material, direct processing at feed point, and replaces static screening plants

Asphalt Recycling – RAP Processing in Brazil

Recycled asphalt pavement contains high-quality aggregates coated with asphalt cement, making it valuable for reuse in new production. However, proper crushing and screening are essential before reintegration. A Brazilian asphalt producer found that traditional mobile crushing required multiple machines and operators, leading them to seek a more efficient solution. The ALLU DS 4-12 with TS 16 drums transformed their operation into a one-machine, one-operator process.

- Application: RAP (Reuse Reclaimed Asphalt) processing for production

- Screening Buckets: DS 4-12 with TS 16 drums

- Benefits: High capacity processing, significant cost reduction, efficient operation

Asphalt Waste Processing and Recycling – USA

Construction sites generate massive amounts of asphalt waste, which often ends up in landfills. ALLU’s DL 2-17 Transformer with 16/32mm AXE blades offers a smarter, more cost-effective way to handle this problem. Bellamy Paving in New Jersey found a solution that transformed their business by turning asphalt waste into reusable material, reducing disposal costs and boosting sustainability.

- Application: Asphalt waste processing and recycling

- Screening Buckets: DL-Series

- Benefits: Reduced landfill fees and transportation costs, processed 90% of waste asphalt for reuse

Recycled asphalt processing in Finland

Finland’s leading asphalt contractor, Asfalttikallio, faced a complex challenge at their advanced Ylöjärvi facility: efficiently processing recycled asphalt blocks while maintaining strict quality standards for their high-content recycled mixes. ALLU’s DS 3-23 Screening Bucket with TS25 drum delivered a solution, significantly reducing processing costs while ensuring consistent material quality. The on-site processing capability transformed their operation, eliminating the need for expensive mobile crushers.

- Application: Recycled asphalt processing

- Screening Buckets: ALLU DS 3-23 with TS25 blades

- Benefits: Substantial cost reduction in processing, on-site material processing, direct production integration, consistent quality control

Getting Started with ALLU

Take these simple steps to improve your asphalt processing efficiency with ALLU:

- Schedule a free consultation: Our team will connect with you to understand your asphalt processing needs and recommend the best solutions for handling road planings, oversized chunks, and sticky materials.

- Receive customized recommendations: We’ll provide expert advice tailored to your asphalt operations, along with a no-obligation quote.

- Proceed with confidence: Once you’ve chosen your solution, we’ll take care of the order processing and ensure a smooth and timely delivery.

- Count on global support: After your purchase, our international support team will be there to assist you whenever needed, ensuring uninterrupted operations.

ALLU’s D-Series screening and crushing buckets are designed to improve the efficiency of your asphalt processing operations, minimize downtime, and enhance productivity. Start today and discover how ALLU can transform your asphalt waste into valuable resources.

D-Series Features

The ALLU Transformer D-Series Screening and Crushing Buckets provide an efficient and practical way to process asphalt and road planings for reuse. Tackling sticky, oversized asphalt chunks and road maintenance waste, these versatile attachments turn challenging materials into high-quality, reusable resources. Mounted on excavators or loaders, the ALLU D-Series efficiently screens, crushes, and loads asphalt waste in a single, seamless operation—eliminating the need for multiple machines and significantly cutting costs.

The screening and crushing buckets specialize in:

- Flexible Processing – Adapt to different asphalt types, from road planings to large, sticky chunks, using interchangeable drum setups.

- On-site Operation – Process asphalt waste directly at the demolition or storage site, avoiding costly transport and double handling.

- Cost Reduction – Minimize disposal fees by turning asphalt waste into reusable materials or saleable products.

- Environmental Benefits – Support recycling efforts by reducing landfill waste and cutting down transport emissions.

CUSTOMER STORIES

Can’t find the right solution? Explore our other applications, from mining to composting.

- Demolition

- Composting

- Construction

- Aerating

- Utility and road works

- Pipeline padding

- Solar padding

- Asphalt recycling

- Waste rock handling

- Concrete recycling

- Topsoil screening

- Waste processing

Book a free consultation

With the ALLU D-Series and DHA-Series Screening Crushing Buckets, you’ll ensure smoother everyday operations while converting raw materials into more valuable forms.

Don’t wait – get your job done easier with ALLU!