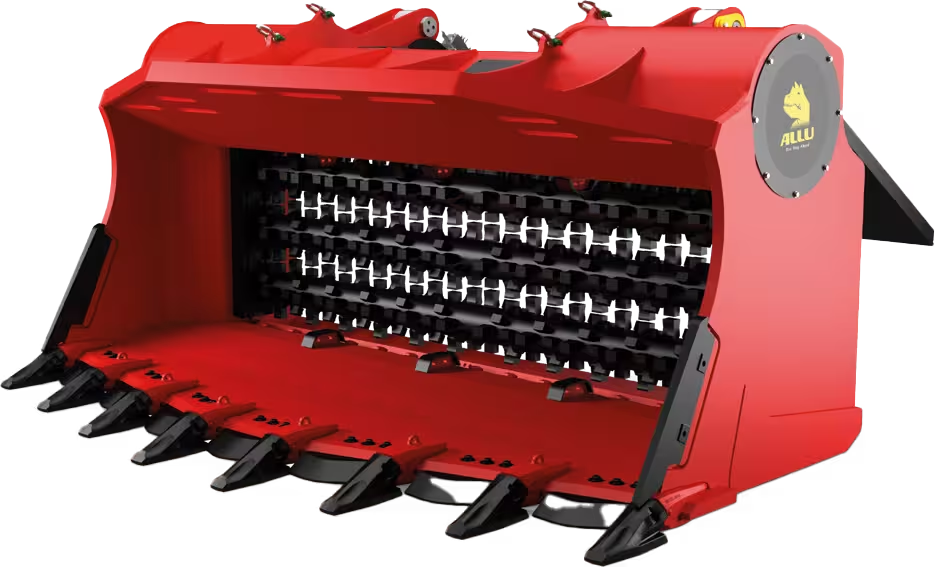

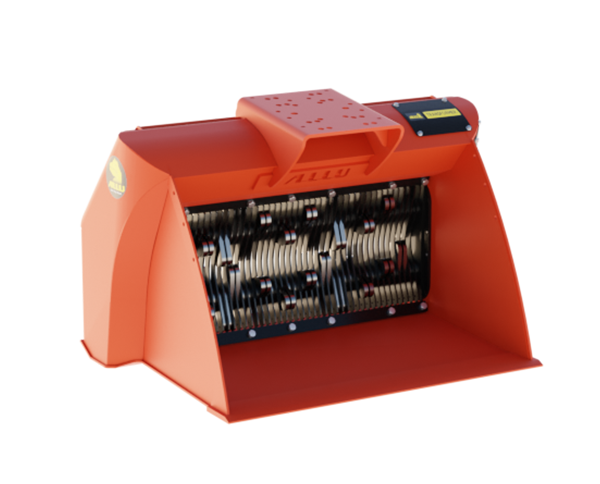

LIGHTWEIGHT DL-SERIES

Are you tired of wasting time and money on your job site? DL-Series is designed to make your work more efficient. Whether you’re working with soil, sand, gravel, compost, demolition waste, or biomass – DL-Series Screening Bucket makes your work easier.

With DL-Series Screening Bucket you can:

- Easily screen and separate various materials: Handle a wide range of materials, from soil and sand to demolition waste and biomass.

- Improve your work efficiency and productivity: Save time and reduce the need for multiple machines with our all-in-one solution.

- Reduce waste and meet sustainability regulations: Minimize landfill waste and promote a circular economy by reusing valuable materials.

- Adapt to different job site requirements effortlessly: Customize the screening bucket to fit the specific needs of each project.

Key features of the screening bucket:

- Versatile Applications: Perfect for landscaping, agriculture, waste management, and biomass processing.

- Multiple Sizes: Available in three sizes to fit excavators, wheel loaders, tractors, and skid steers.

- Efficiency: Screen, crush, aerate, mix, and load in a one-step operation.

- Environmental Benefits: Less transportation reduces fuel consumption, and reusing materials minimizes landfill waste.

- Economic Advantage: Reduce costs by reusing materials on-site and creating high-quality end products.

Applications for DL-Series Screening Bucket

ALLU offers a wide range of screening bucket models in various sizes to meet the needs of different industries. These buckets are designed for installation on excavators, wheel loaders, tractors and skid steers.

PIPELINES AND UTILITY TRENCHES

Screening Bucket DL-Series is perfect for screening and backfilling water pipelines and utility trenches. It also works great for cable trenches in places like solar panel parks. Adapt the bucket to screen different materials back into the trench as needed.

TOPSOIL, AGRICULTURE AND LANDSCAPING

The DL-Series is ideal for topsoil screening, composting, handling manure, and more. Enhance your work efficiency and produce high-quality end products.

WASTE RECYCLING

Efficiently screen, separate, and even crush various waste materials. Help recycle valuable materials such as wood, plastic, and metals, promoting sustainability.

BIOMASS PROCESSING AND COMPOSTING

Handle biomass and composting materials effectively. Ensure the quality of high-grade biomass fuel for energy production.

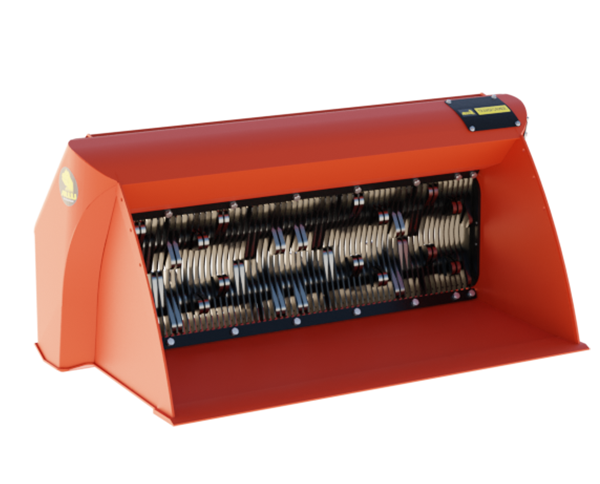

DL-Series models

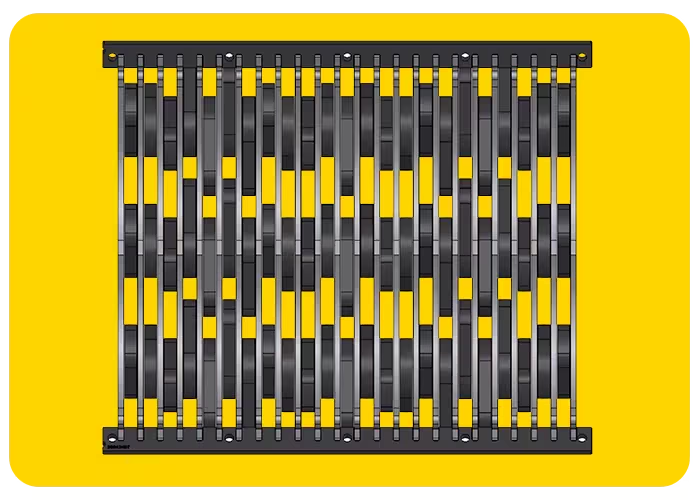

Our DL-Series Screening Bucket adapts to the material being processed thanks to the numerous drum and blade options that can be installed in the bucket. The first number in the model name is the number of drums and the last number is the width of the bucket e.g. 12 means 1200mm.

DL 2-09

DL 2-12

DL 2-17

Technical Specifications

| Excavator | 4 – 12 t |

| Wheeloader | 2 – 8 t |

| Volume | 0.27 – 0.37 m3 |

| Oil flow | 60 – 90 LPM |

| Weight | 430 kg |

| Excavator | 7 – 12 t |

| Wheeloader | 3 – 8 t |

| Volume | 0.37 – 0.52 m3 |

| Oil flow | 60 – 90 LPM |

| Weight | 540 kg |

| Excavator | 9 – 12 t |

| Wheeloader | 4 – 8 t |

| Volume | 0.51 – 0.75 m3 |

| Oil flow | 60 – 90 LPM |

| Weight | 695 kg |

How to get started?

Follow these easy steps:

- Request a free consultation: Our experts will contact you to discuss your specific needs.

- Get personalized recommendations: We’ll provide tailored advice and a no-obligation quote.

- Move forward with confidence: Once you decide, we’ll process your order and arrange delivery.

- Have global professional support: After your purchase, we make sure that you’ll have support whenever you need it.

With the ALLU DL-Series, you can streamline your operations, save money, reduce environmental impact, and increase profits. Don’t wait – get your job done easier with ALLU!

BETTER FOR YOU

BETTER FOR THE ENVIRONMENT

DL-Series features

ALLU DL-Series Screening Buckets are designed for all sorts of material handling jobs, from compost aeration to landscaping and construction waste treatment, not forgetting pipeline backfilling. This is a hydraulic attachment for excavators, loaders, and skid steers that screens, crushes, aerates, mixes, separates, feeds and loads materials in a one-step operation.

Efficient – process materials fast and efficiently in one step

Mobile – converts your base machine into a mobile processing plant

Greener – smaller carbon footprint and reduced material transportation costs

Plug & play – simple installation to excavators, wheel loaders and skid steers

Multiple configurations – change between different fragment sizes and applications

Powerful – works well even with wet materials

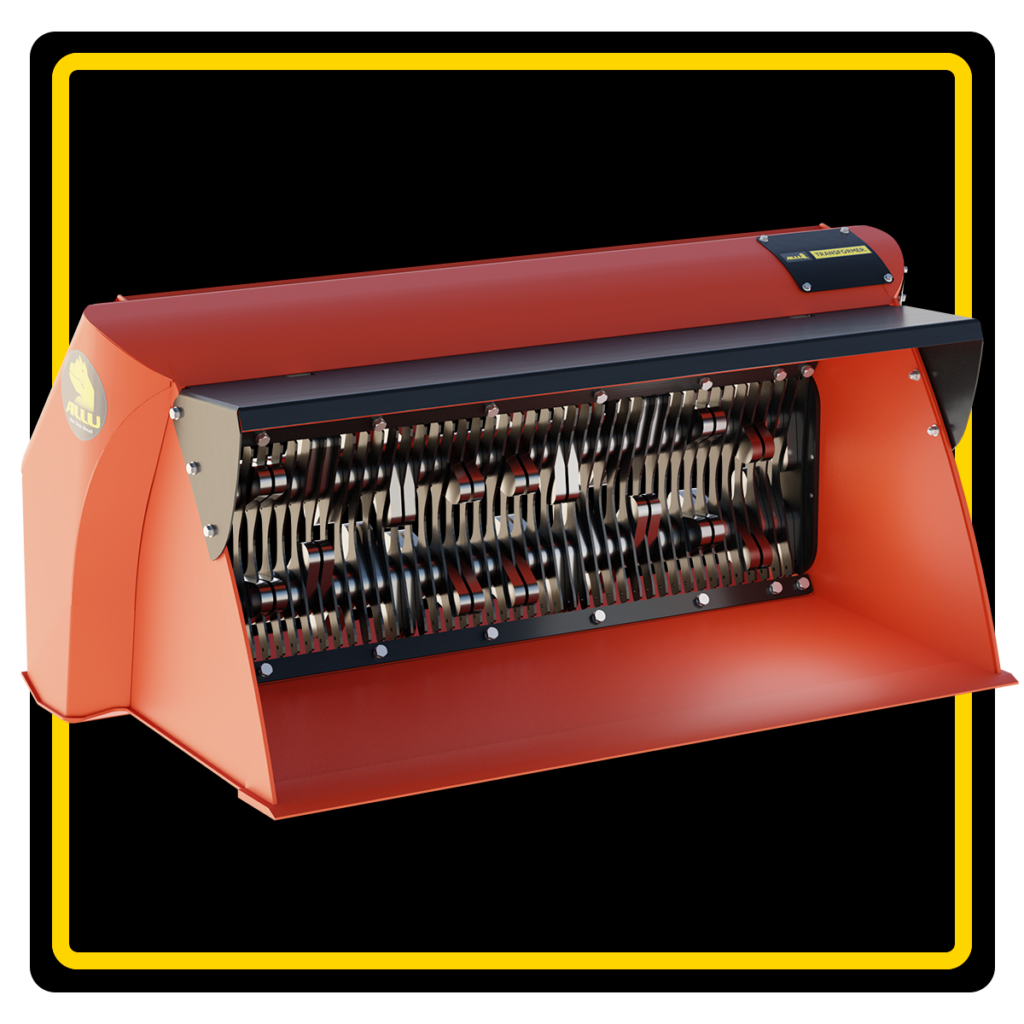

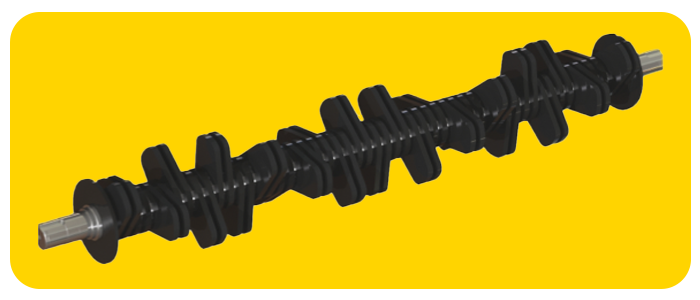

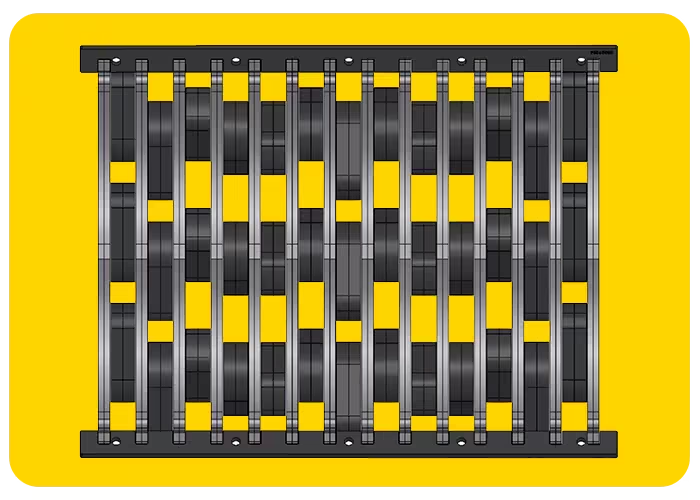

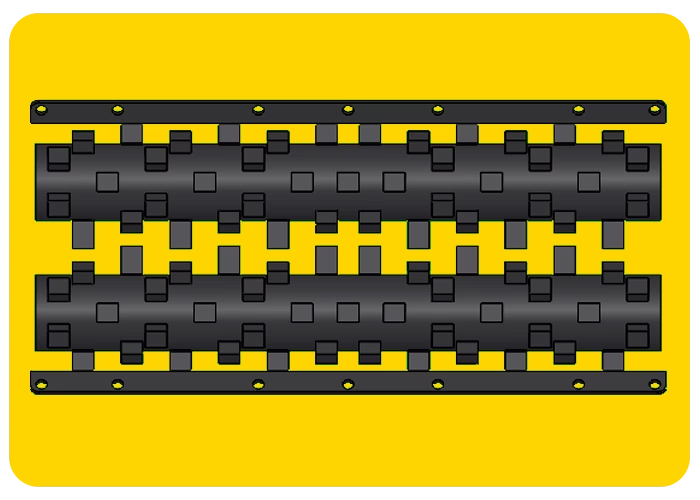

DRUMS & BLADES

MULTIPLE CONFIGURATIONS

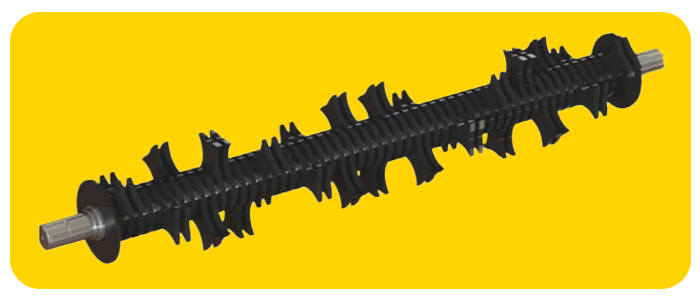

TS SCREENING DRUM

- Changeable blades

- Change fragment size without dismantling drums with doubling option

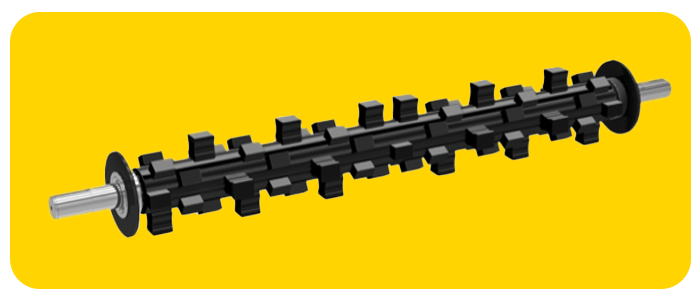

TS AXE CRUSHING DRUM

- Changeable blades

- Change fragment size without dismantling drums with doubling option

X50 DRUM

- Changeable blades without dismantling drums

Get in touch

With the ALLU Screening Bucket DL-Series, you can streamline your operations, save money, reduce environmental impact, and increase profits. Don’t wait – get your job done easier with ALLU!

Main Application Areas

- Aerating

- Screening

- Composting

- Pipeline padding

- Waste material handling

- Landscaping

DL-SERIES CASE STUDIES

ROBUST – RELIABLE – ADVANCED

ALLU Tracker

Keep your equipment safe and monitor their use with the ALLU data tracker.

- Easily mounted data tracking devices in an IP69k design. Battle-proven and tested under the harshest of circumstances.

- Monitor running hours based on motion.

- Worldwide GSM network coverage with LTE and 2G fallback. The data logging feature ensures data is stored if networks are unavailable.

- Devices can always be located with built-in GPS or network triangulation positioning.

- Manage online from anywhere, all hardware is managed online on the ALLU Data Portal.

ALLU Tracker has a long battery life of up to 5 years. Due to its small size (68 x 68 x 25 mm) and easy mounting with magnet, it doesn’t interfere with the structural integrity of the ALLU products.

Didn’t find what you were looking for?

Get to know our other Screening Bucket products, and find the perfect one for you. If you need help finding the perfect option for you, please get in touch with us and we’ll guide you.