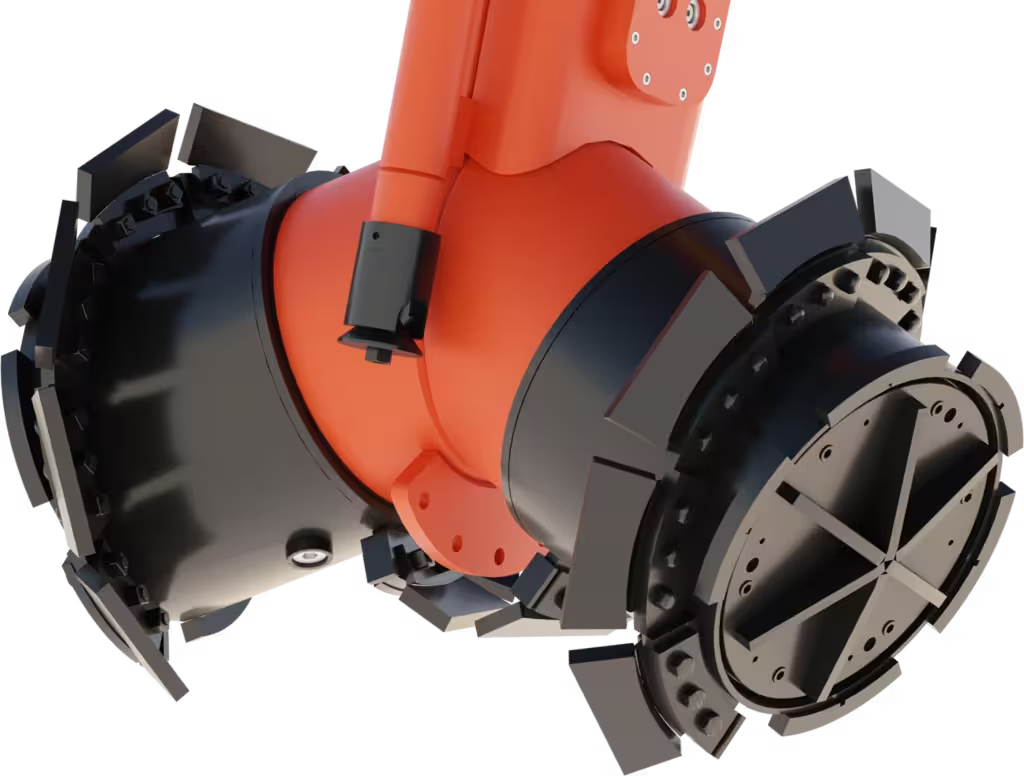

ALLU Soil Improvement products for stabilization, solidification, and remediation of soft soils and sediments

ALLU provides solutions for soil improvement through its range of soil stabilization products. These products are designed to enhance the quality and characteristics of different types of soils, making them more suitable for construction and infrastructure projects.

ALLU soil stabilization products are capable of effectively stabilizing various soil types, including clay, silt, peat, and others. They can handle different soil conditions and adapt to specific project requirements. The products are designed for efficient mixing and full control over the binder feed. They ensure thorough and even distribution of additives throughout the soil, promoting consistent stabilization and a homogeneous result.

ALLU’s soil improvement solutions offer potential cost and time savings for construction projects. By optimizing existing soils instead of relying solely on extensive excavation and replacement, they reduce the need for additional materials, transportation, and project timelines.

By utilizing ALLU soil improvement products, construction projects can reduce the environmental impact associated with sourcing and transporting new materials. Soil stabilization promotes sustainable construction practices by maximizing the use of existing resources.

Request a free consultation

With the ALLU Soil Improvement System, you can streamline your operations and save money. Our experts are here to help you find the perfect solution that fits your needs.

Don’t wait – get the job done faster with ALLU!