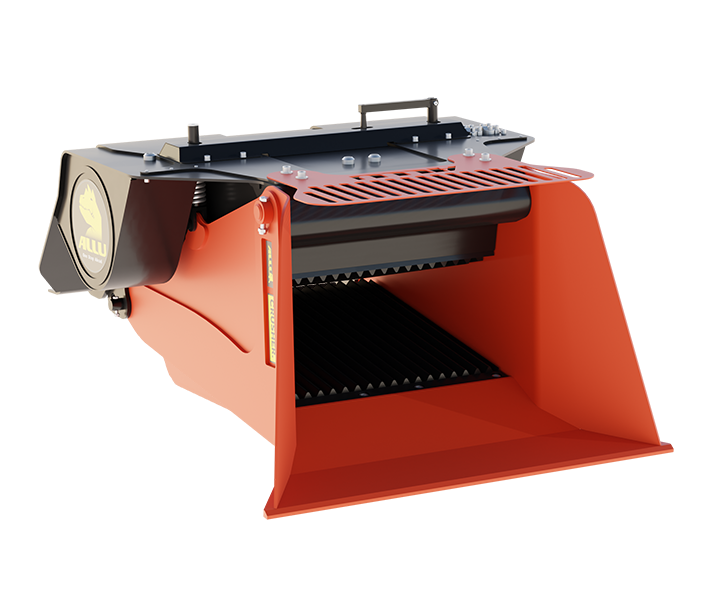

Crusher bucket

ALLU Crusher Bucket – Crush and recycle on-site

ALLU Crusher Bucket is a crusher attachment for excavators. It is designed to crush and reduce various materials, such as concrete, stone, demolition waste, asphalt, and natural rock.

The crushing bucket operates on the principle of a jaw crusher, allowing for crushing and recycling of materials on-site.

ALLU Crusher Bucket is designed to increase efficiency and productivity in construction and demolition sites by reducing the need for traditional crushing equipment and streamlining the material handling process.

The bucket can be easily attached to excavators, providing a cost-effective solution for material processing tasks.

This excavator crusher attachment enables material recycling directly on the job site, eliminating the need to transport materials to external processing facilities. This saves on transportation costs, time, and resources while reducing environmental impact. It can be used for both primary and secondary crushing tasks.

Key features of crushing buckets

The ALLU Crusher Buckets are available in different sizes to fit various excavators and applications.

They come with features such as adjustable particle size, two way jaw crushing, and interchangeable crushing plates that optimize performance and durability. This enables the operator to produce crushed materials of different sizes to meet the requirements of the job site.

By crushing and recycling materials on-site, the ALLU Crusher Bucket optimizes resource utilization and reduces the need for raw materials. It supports sustainable practices and waste reduction in various industries.

The ALLU Crusher Bucket brings with it numerous advantages, including:

- Cost and time savings: Crushing material on-site reduces the need for transportation to a separate processing facility, resulting in cost and time savings.

- Increased efficiency: Enables the immediate processing of materials without the need for machinery or processes located outside the job site, leading to increased efficiency.

- Environmental benefits: Recycling and reusing materials reduce environmental impacts associated with traditional disposal methods of materials.

- Versatility: Can be used in various applications, including construction, demolition, road building, and landscaping.

ALLU Crusher Bucket Series

AC 8-15

AC 25-37

AC 10-16

AC-30-47

AC 20-22

AC 5-17FD

for skid steers

Technical Specifications

| Skid Steer (t / lbs) | 4-6 / 9,000-13,000 |

| Weight (kg / lbs) | 1750 / 3,860 |

| Operating Pressure (bar / psi) | 240 / 3480 |

| Max. Operation Flow (LPM / gpm) | 90 / 24 |

| Loading Capacity (m3 / yd3) | 0.4 / 0.52 |

| Crushing Cam Opening (mm / in) | 360 / 14.2 |

| Output Size Regulation (mm / in) | 0-16 / 0-0.63 to 0-7.9 (6 step) |

| Excavator (t / lbs) | 8-11 / 18,000-24,000 |

| Weight (kg / lbs) | 1400 / 3,090 |

| Operating Pressure (bar / psi) | 250 / 3600 |

| Max. Operation Flow (LPM / gpm) | 80 / 21 |

| Loading Capacity (m3 / yd3) | 0.35 / 0.46 |

| Crushing Cam Opening (mm / in) | 260 / 10 |

| Output Size Regulation (mm / in) | 0-16 to 0-200 / 0-0.63 to 0-7.9 (6 step) |

| Excavator (t / lbs) | 10-14 / 22,000-31,000 |

| Weight (kg / lbs) | 1740 / 4,050 |

| Operating Pressure (bar / psi) | 250 / 3600 |

| Max Operation Flow (LPM / gpm) | 95 / 25 |

| Loading Capacity (m3 / yd3) | 0.35 / 0.46 |

| Crushing Cam Opening (mm / in) | 370 / 14.6 |

| Output Size Regulation (mm / in) | 0-16 to 0-200 / 0-0.63 to 0-7.9 (6 step) |

| Excavator (t / lbs) | 15-22 / 33,000-49,000 |

| Weight (kg / lbs) | 2465 / 5,640 |

| Operating Pressure (bar / psi) | 250 / 2600 |

| Max. Operation Flow (LPM / gpm) | 160 / 42 |

| Loading Capacity (m3 / yd3) | 0.5 / 0.65 |

| Crushing Cam Opening (mm / in) | 370 / 14.6 |

| Output Size Regulation (mm / in) | 0-16 to 0-200 / 0-0.63 to 0-7.9 (6 step) |

| Excavator (t / lbs) | 23-35 / 51,000-77,000 |

| Weight (kg / lbs) | 3820 / 8,820 |

| Operating Pressure (bar / psi) | 250 / 3600 |

| Max. Operation Flow ( LPM / gpm) | 180 / 47 |

| Loading Capacity (m3 / yd3) | 1.0 / 1.31 |

| Crushing Cam Opening (mm / in) | 370 / 14.6 |

| Output Size Regulation (mm / in) | 0-16 to 0-200 / 0-0.63 to 0-7.9 (6 step) |

| Excavator (t / lbs) | 26-38 / 62,000-84,000 |

| Weight (kg / lbs) | 5540 / 12,210 |

| Operating Pressure (bar / psi) | 25 / 3630 |

| Max. Operation Flow ( LPM / gpm) | 200 / 53 |

| Loading Capacity (m3 / yd3) | 1.2 / 1.6 |

| Crushing Cam Opening (mm / in) | 440 / 17.3 |

| Output Size Regulation (mm / in) | 0-16 to 0-200 / 0-0.63 to 0-7.9 (6 step) |

TURN YOUR EXCAVATOR INTO MOBILE CRUSHING PLANT

Maximum productivity

-

- Increase your excavator utilisation rate

-

- Easy to handle, even in tight and limited areas

-

- No need for logistics or permissions

-

- Quick to put into operation

-

- Easy to change fragment size

Robust, practical design

-

- Can be run in reverse to unluck jamming

-

- High torque motors enable start up with a full load

-

- Opens like a clam for safe and easy replacement of upper jaw

Environmentally friendly

-

- Reducing material sent to landfill, and increasing your profits.

-

- Increasing your sustainability and profits, by reducing transportation costs.

Crusher Features

ALLU Crusher is a hydraulic crushing attachment for conventional excavators from 8 – 33 tons. It is designed to effectively crush and recycle demolition materials, building rubble, natural stones, asphalt materials, concrete, and construction debris.

1. Mainframe

2. Upper jaw – safe and easy to replace

3. Crushing plates – allow material to flow freely through jaws

4. Streamline wear-resistant frame – no external parts for a long-lasting operational life

5. Straight side and angled tip plates – provide a rigid frame, reduce the wear, and provide a higher crushing filling rate

6. Adjustable pin – for quick fragment size changes

7. Protected belt drive – maintenance-free no adjustment

Main Application Areas

- Demolition

- Excavation

- Construction

- Utility and Road works

- Concrete Waste Recycling

- Asphalt Recycling

- Waste Rock Handling at quarries

- Concrete Pipe Industry

- Brick and Ceramics Industry

Want to know more? Get in touch

With the ALLU Crusher, you’ll enjoy enhanced flexibility, increased efficiency, faster project completion, lower operational costs, and reduced environmental impact.

Don’t wait – make your job smoother with ALLU!

ROBUST – RELIABLE – ADVANCED

ALLU Tracker

Keep your equipment safe and monitor their use with the ALLU data tracker.

- Easily mounted data tracking devices in an IP69k design. Battle-proven and tested under the harshest of circumstances.

- Monitor running hours based on motion.

- Worldwide GSM network coverage with LTE and 2G fallback. The data logging feature ensures data is stored if networks are unavailable.

- Devices can always be located with built-in GPS or network triangulation positioning.

- Manage online from anywhere, all hardware is managed online on the ALLU Data Portal.

ALLU Tracker has a long battery life of up to 5 years. Due to its small size (68 x 68 x 25 mm) and easy mounting with magnet, it doesn’t interfere with the structural integrity of the ALLU products.

RELATED PRODUCT

PARTNER YOUR CRUSHER WITH ALLU SCREENING BUCKET

The ALLU Crusher and ALLU Screening Buckets support each other. Both functions are often needed at the same job site and are complimentary. By pre-screening the material with the ALLU Screening Bucket the capacity of the ALLU Crusher will increase because the fine material has been screened away. If the material is wet, fine material often tends to clog. This causes jamming and bridging. Furthermore, the quality of the desired end product will significantly improve. Re-use of pre-screened material; can be utilized as fill material.

-

- One base machine and operator needed

-

- Low investment costs

-

- Full mobile solutions for any job site

-

- Increase the overall capacity

-

- Less landfill payments – lower dumping costs