We are all aware of the environmental impact of coal ash in the US. With potential hazards to both the air and water being a concern to all parties involved. Loose particles of fly ash can float in the air to surrounding communities, causing various respiratory issues to nearby residents. Both abandoned and operational ash ponds have a high potential to seep into the groundwater carrying chemicals such as lead, arsenic and mercury to the municipal water supply.

What to do with these ponds has been the center of much debate throughout the power generation providers along with environmental advocates. Finding an acceptable solution that would provide a safe permanent, solution that was economically feasible has been a challenge. The EPA permits two methods, closure in place and closure by removal. Each method presents its own challenges and downsides.

Closure in place or “capping” the pond is typically done using a process known as “bucket mixing” which is accomplished by dumping sacks of powdered binder (usually Portland Cement) onto the surface of the pond. The binder is then mixed using the buckets of a tracked excavator. A shallow cap is formed as the cement hardens. Though much less expensive than removal. The main problem exists beneath the “cap” moisture remains in the unstable contaminated soil allowing continued seepage into the groundwater. The capped ground is unsuitable for building and difficult to repurpose, additional dust pollution is also created during the bucket mixing process.

Removal minimizes the overall risk of groundwater pollution but presents its own set of problems. Compared to closure-in-place costs, removal costs and time can add up to more than five times that of in-place closure. Relocation to an approved dump site (landfill) may also prove difficult with dust and contaminants being released during transport. Regulation of the dump site can also be difficult. If not properly maintained these sites can be affected by the wind carrying the reclaimed dust at great distances. Stormwater can seep through the ash and continue to contaminate groundwater.

Deep pond stabilization provides an innovative solution that solves problems present in both capping and removal. The ALLU Soil Stabilization system has been used throughout Europe for more than a decade. The system uses a powerful mixing head attached to the boom of a mid-sized excavator. The mixing head is fed a dry binder by a computer-controlled high-pressure feeder creating a homogeneous mix. Unlike bucket mixing; the system is capable of depths beyond 20’. The ash pond is stabilized from the bottom up and not just at the surface. The feeding system regulates with precision the exact amount of binder prescribed by the engineer to fully encapsulate the contaminated site.

Because it is now a solid mass. Potential groundwater contamination along with dust pollution from wind, rain, or during transportation are eliminated. Costs are controlled by removing the need to build and maintain dump sites. Less fossil fuels are used without the need to transport to an off-site location. A solid surface remains that continues to harden over time allowing a re-purposing of the existing ash containment pond. A truly green solution.

There are hundreds of coal ash ponds in the USA, ash pond waste contains heavy metals, which leach into nearby groundwater, and surface water is the second biggest flow of waste material in the USA.

Coal combustion residuals (CCRs), commonly known as coal ash, are by-products of the combustion of coal at power plants operated by electric utilities and independent power producers. The environmental impacts are high with many sites leaking into the water course, causing pollution and major issues as you can see from the map. Many sites are not lined, and the raw waste material continues leaking into the water course.

Finding a permanent solution to this ongoing environmental issue has been a challenge for over a decade. The traditional method known as “bucket mixing” has no binder control which can, high cost and a lot of dust pollution with non-homogenized results. The treated site is only stabilized on the surface which allows continued leeching into the soil beneath the surface.

Solution

ALLU is one step ahead reducing costs up to 40%, providing a fast effective and environmentally friendly work method for the hardening and dynamic strengthening contaminated soft soils, as well as improving the soil’s deformation properties. It is designed to improve soft soils by mixing a binder into clay, peat, mud, or dredged sediments. The method can also be used in the treatment of contaminated soils, by encapsulating contaminants within the ground and preventing migration to the surrounding areas.

The Allu system consists of three components:

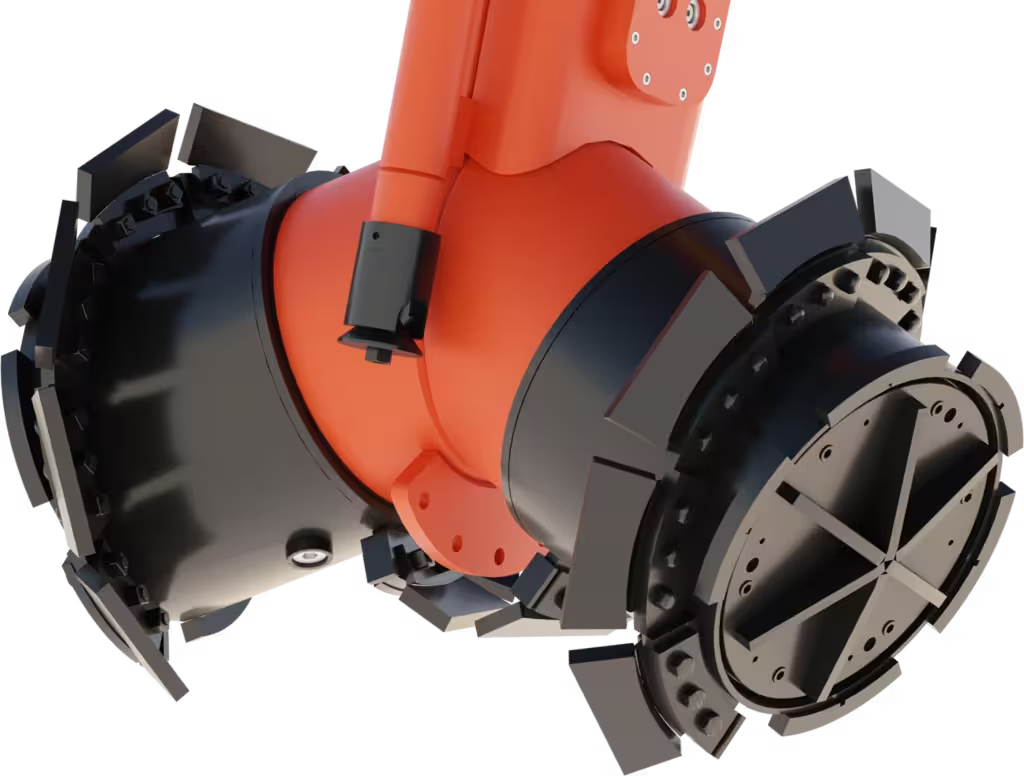

The first is the power mix attachment mounted to the dipper arm of a suitable excavator, using a pin mounting or quick-hitch adaptor plate. At the end of this substantial attachment, a pair of mixing/ cutting drums are used to mix the binder material into the ground in a controlled manner. The unit can process different materials to a depth of six meters, depending on the choice of the power mix model, the excavator’s reach and the quality of the material.

The second component is the pressure feeder mounted on a powered crawler chassis. This injects the binder into the ground by compressed air via hoses. The amount of binder per square meter can be controlled, depending on the requirement for the prevailing ground conditions.

The third component in the Allu system is the data acquisition control (DAC), located in the excavator’s cab. This controls, measures and stores data on the stabilisation project. On site, the flow and pressure of the binder are adjusted by the excavator operator via the DAC, and it seems reasonably easy to use and enables the binder to be fed at optimum rates. Back in the office, the DAC provides an extensive report for the entire duration of a project, the data being transferred into a computer via a USB port.

Its potential as a sustainable solution with a valid mixing method and homogeneous results, causing less dust pollution and reducing binder costs, demonstrates why the system has already been successfully used in different ground conditions and interest is certainly being generated.