Meet ALLU Asphalt at CONEXPO-CON/AGG 2026

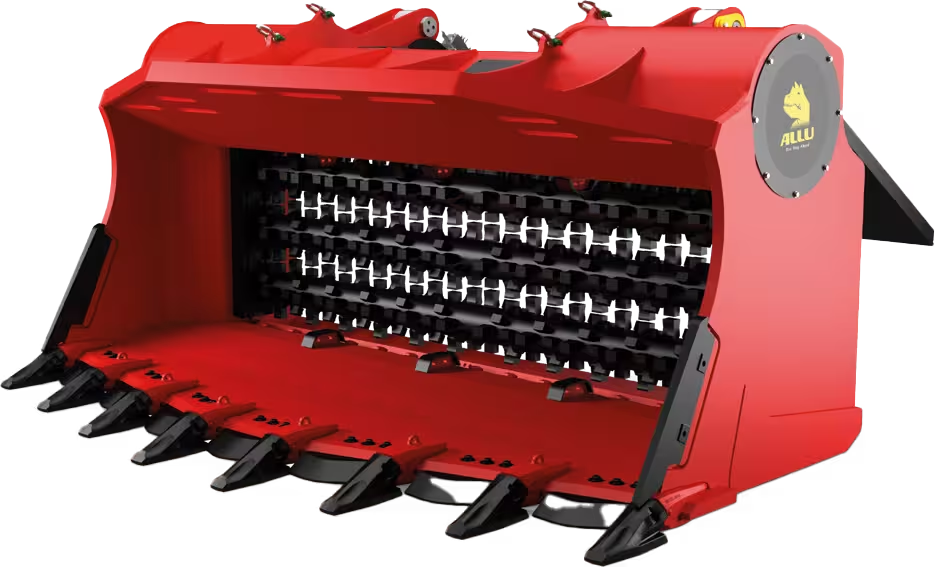

The ALLU Asphalt Screening bucket is designed specifically for cold-milled and reclaimed asphalt (RAP). It crushes clumps, screens fine material, and separates oversized particles – all in a single pass. Thanks to its innovative hybrid blade setup, you get just the right amount of crushing power combined with efficient screening.

By handling the majority of the material directly with the ALLU bucket, you drastically reduce the need for expensive impact crushers, cutting down on fuel consumption, wear part replacements, and operating hours. This results in significant savings in both time and money, making the process not only more efficient but far more profitable.

Whether you’re processing 100 or 250 tons per hour, ALLU helps you optimize your recycled asphalt handling – keeping your fleet productive and your bottom line strong.

Efficiency Meets Profitability

The Asphalt Bucket utilizes a hybrid blade configuration – a mix of screening and crushing blades – to fine-tune performance and achieve consistently high-quality end products. This combination allows operators to process cold-milled asphalt directly at the source without additional crushing equipment.

With nominal screen sizes of 12, 16, and 25 mm, the bucket can produce over 95% of finished material below target size, drastically reducing reprocessing needs.

Key features include:

- One-Step Operation: Crushes and screens simultaneously, eliminating the need for separate pre-crushing or secondary equipment.

- Lower Total Costs: Reduces reliance on mobile impact crushers, cutting fuel consumption, wear part expenses, and overall ton-per-cost rates.

- Proven Throughput: Models deliver up to 250 tons per hour, with rapid drum change-outs thanks to the Variable Drum technology.

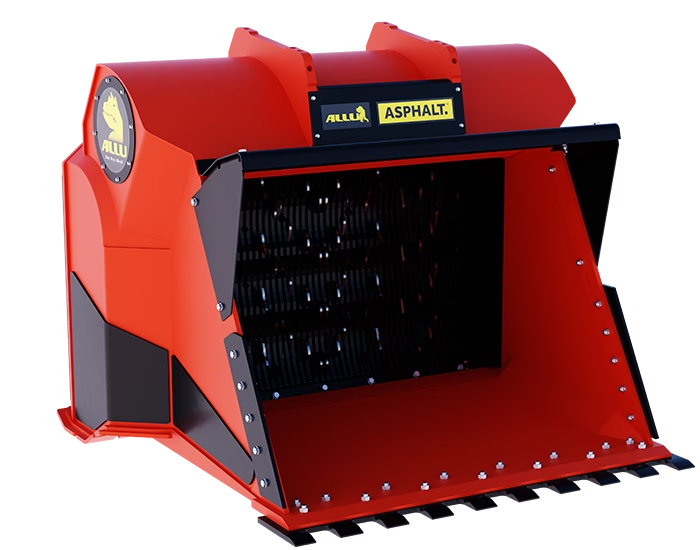

Variable Drum at CONEXPO

The screening bucket we presented at our stand is a special concept bucket with all possible drum options – TS – X and XHD. It’s built on a DN 3-12 frame, showing the versatility of one ALLU bucket. In real life, mixing different drums is not possible. Not yet anyway…

Read more in English Mehr lesen auf Deutsch Lire plus en français

You can use all our drum types in the same frame without opening the chain drive and making modifications to the technical structure. With ready drum kits at hand, changing the configuration of the bucket is fast and simple.

The ALLU Variable Drum brings next-level efficiency to material processing, allowing you to switch between screening and crushing without delays. With its quick 2-bolt locking system, operators can replace drums and blades without accessing the drive compartment, significantly reducing service time. Defeat downtime with one frame and endless applications.

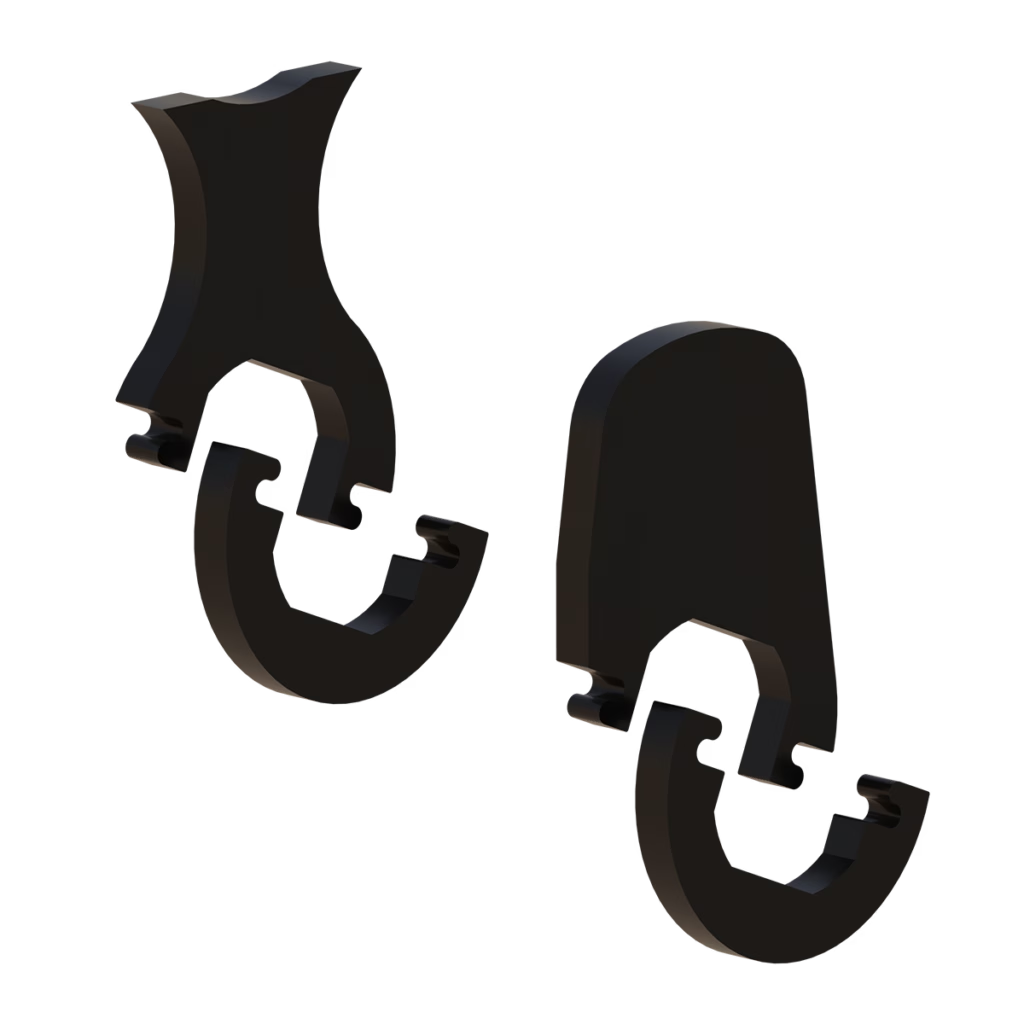

ALLU TSR Blades

The TSR blades (Top Screen Rapid) represent a significant upgrade over the traditional TS blades (Top Screen) for our screening buckets.

Opening the chain box and removing the drums to install new blades on the shafts can be demanding. The TSR blades streamline maintenance with their innovative 2-piece structure, allowing for individual blade replacement directly on the shaft without the need to disassemble the drum or open the chain box.

Changing the blades on one drum with TSR blades takes almost 2 hours less compared to the standard blades. See a time-lapse video here.

TSR and TS blades can be used on the same bucket. You can have TSR blades just on the upper drum, which is exposed to more wear than other drums, and standard TS on the lower ones.

The largest Construction Show in North America is back 3.-7.3.2026!

40 Years of Expertise at Your Service

ALLU is a family business that designs and manufactures screening and crushing buckets for the processing, separation, sorting, mixing, and crushing of materials. Typical applications include soil and waste recycling, the treatment of contaminated soil, and the transformation of waste into usable materials.

For four decades, ALLU has provided innovative solutions and expertise in the field of material handling. With a strong commitment to customer satisfaction and continuous improvement, ALLU has established itself as a reliable partner in various industries worldwide. Our headquarters are in Finland, and we operate globally with over 100 local dealers in more than 30 countries.

Get to know ALLU Products

Get to know ALLU Screening Buckets and ALLU Soil Improvement System, find the perfect one for you. If you want to understand the ALLU Product portfolio better, please get in touch with us, and we’ll guide you.

Application & Industries

From money-draining to money-making

Whether you’re working in the agriculture, construction, or industrial sectors, ALLU’s solutions are built to meet your needs and help you succeed. Our products are designed to make your work easier, faster, and cheaper. Find out more about how our solutions can work for your industry and start saving money!

ALLU products make your work faster, safer, and more profitable.

Get in touch

With the ALLU Screening Buckets, you can streamline your operations, save money, reduce environmental impact, and increase profits.

Don’t wait – get your job done easier with ALLU!