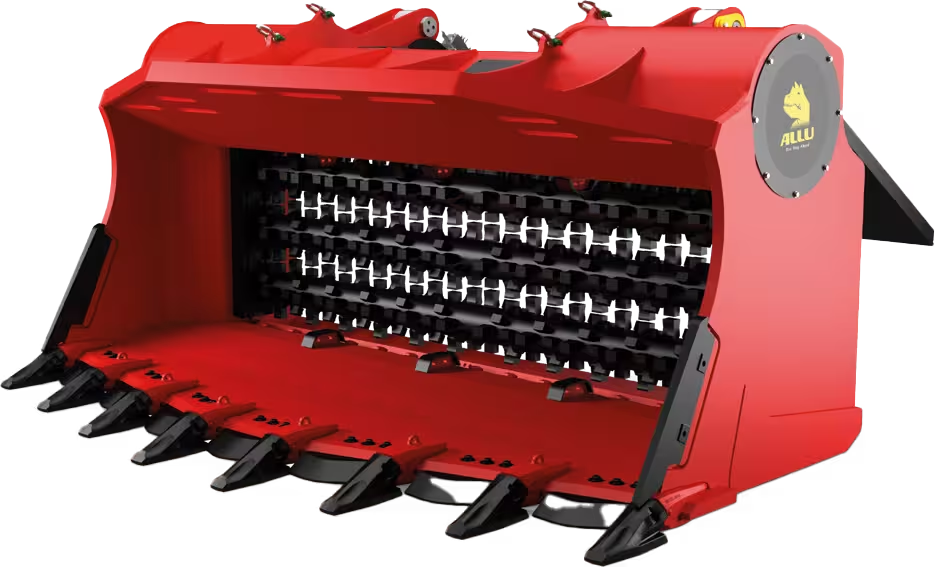

VERSATILE D-SERIES SCREENING BUCKET

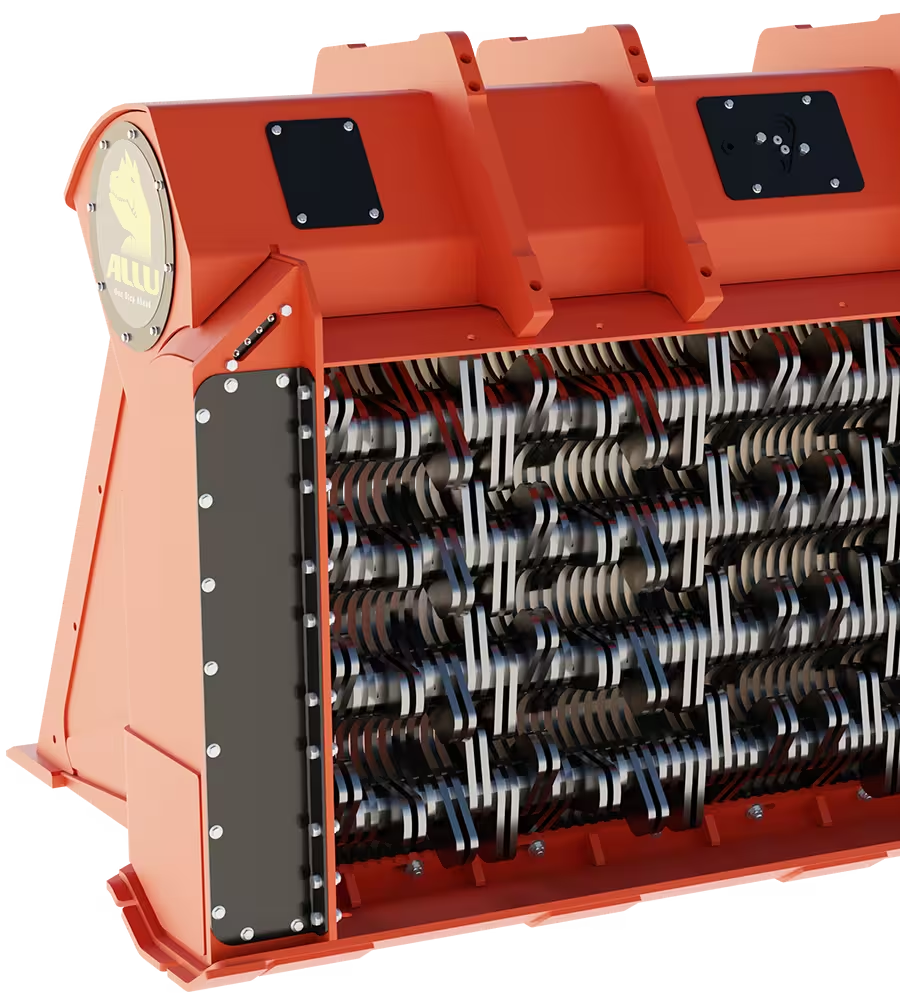

The ALLU D-Series Screening Bucket is a powerful hydraulic attachment for excavators and wheel loaders. It helps you process, screen, crush, and reuse your materials on-site with minimal effort.

Your excavator, tractor, wheel loader, or skid steer will transform into a multifunctional tool that can screen, crush, mix, aerate, pulverize, and load in one simple operation.

Transform your earthmoving machinery into a mobile processing plant with this simple attachment and get your job done faster!

D-Series is a versatile attachment designed for material processing, screening, and recycling applications. It can screen and separate various materials, including different soil types, sand, gravel, asphalt, compost, demolition waste, and biomass, producing end products of different fractions. ALLU Transformer D-Series is suitable for various applications, including construction, excavation, recycling, landscaping, and agriculture.

With the ALLU D-Series Screening Crushing Bucket, you can:

- Screen and separate materials into different sizes.

- Crush, mix, aerate, and load in one operation.

- Process various materials such as soil, sand, gravel, topsoil, compost, waste bark, demolition waste, asphalt, coal and biomass.

- Enhance productivity and cost-efficiency in construction, excavation, recycling, landscaping, and agriculture.

- Save on costs and generate income – to learn how, read on or contact our team!

D-Series models

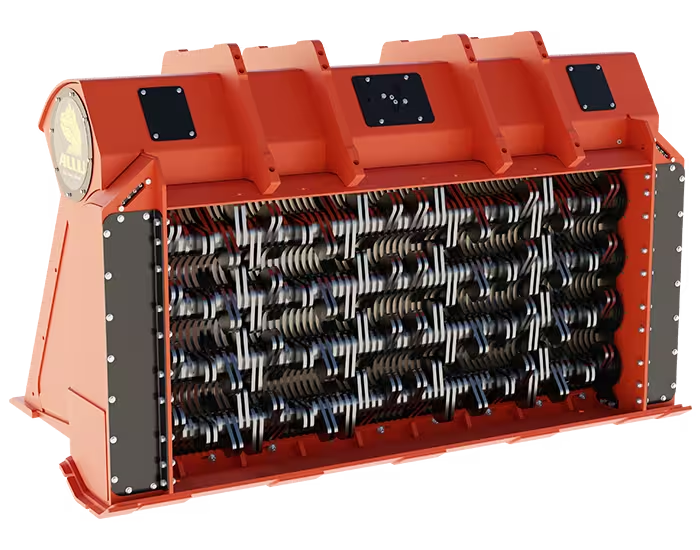

Our D-Series Screening Bucket adapts to the material being processed thanks to the numerous drum and blade options that can be installed in the bucket – either at the factory or as a retrofit. The D-Series consists of three models: DN, DS, and DH. The first number in the model name is the number of drums and the last number is the width of the bucket e.g. 12 means 1200mm.

DN-2-12

DN-3-17

DS-4-23

Technical Specifications

| Excavator | 12 – 28 t |

| Wheel loader | 6 – 14 t |

| Volume | 0.52 – 0.66 m3 |

| Oil flow | 70 – 120 LPM |

| Weight | 1130 kg |

| Excavator | 15 – 28 t |

| Wheel loader | 7 – 14 t |

| Volume | 0.76 – 0.99 m3 |

| Oil flow | 70 – 120 LPM |

| Weight | 1400 kg |

| Excavator | 12 – 28 t |

| Wheel loader | 6 – 14 t |

| Volume | 0.6 – 0.75 m3 |

| Oil flow | 70 – 120 LPM |

| Weight | 1220 kg |

| Excavator | 16 – 28 t |

| Wheel loader | 7 – 14 t |

| Volume | 0.79 – 1.01 m3 |

| Oil flow | 95 – 160 LPM |

| Weight | 1410 kg |

| Excavator | 20 – 28 t |

| Wheel loader | 7 – 14 t |

| Volume | 1.15 – 1.53 m3 |

| Oil flow | 95 – 160 LPM |

| Weight | 1760 kg |

| Excavator | 16 – 35 t |

| Wheel loader | 8 – 22 t |

| Volume | 0.83 – 1.04 m3 |

| Oil flow | 95 – 160 LPM |

| Weight | 1610 kg |

| Excavator | 20 – 35 t |

| Wheel loader | 8 – 22 t |

| Volume | 1.22 – 1.57 m3 |

| Oil flow | 95 – 160 LPM |

| Weight | 2000 kg |

| Excavator | 24 – 35 t |

| Wheel loader | 12 – 22 t |

| Volume | 1.61 – 2.10 m3 |

| Oil flow | 120 – 200 LPM |

| Weight | 2520 kg |

| Excavator | 20 – 35 t |

| Wheel loader | 10 – 22 t |

| Volume | 1.24 – 1.56 m3 |

| Oil flow | 95 – 160 LPM |

| Weight | 1930 kg |

| Excavator | 24 – 35 t |

| Wheel loader | 12 – 22 t |

| Volume | 1.82 – 2.38 m3 |

| Oil flow | 120 – 200 LPM |

| Weight | 2360 kg |

| Excavator | 30 – 35 t |

| Wheel loader | 14 – 22 t |

| Volume | 2.40 – 3.21 m3 |

| Oil flow | 120 – 200 LPM |

| Weight | 3020 kg |

| Excavator | 18 – 45 t |

| Wheel loader | 8 – 30 t |

| Volume | 0.85 – 1.07 m3 |

| Oil flow | 140 – 235 LPM |

| Weight | 1950 kg |

| Excavator | 22 – 45 t |

| Wheel loader | 10 – 30 t |

| Volume | 1.25 – 1.62 m3 |

| Oil flow | 140 – 235 LPM |

| Weight | 2400 kg |

| Excavator | 26 – 45 t |

| Wheel loader | 14 – 30 t |

| Volume | 1.65 – 2.16 m3 |

| Oil flow | 140 – 235 LPM |

| Weight | 2960 kg |

| Excavator | 22 – 45 t |

| Wheel loader | 10 – 30 t |

| Volume | 1.26 – 1.59 m3 |

| Oil flow | 140 – 235 LPM |

| Weight | 2280 kg |

| Excavator | 27 – 45 t |

| Wheel loader | 14 – 30 t |

| Volume | 1.85 – 2.43 m3 |

| Oil flow | 140 – 235 LPM |

| Weight | 2780 kg |

| Excavator | 32 – 45 t |

| Wheel loader | 16 – 30 t |

| Volume | 2.43 – 3.27 m3 |

| Oil flow | 190 – 315 LPM |

| Weight | 3490 kg |

| Excavator | 36 – 45 t |

| Wheel loader | 18 – 30 t |

| Volume | 3.02 – 4.12 m3 |

| Oil flow | 240 – 400 LPM |

| Weight | 4080 kg |

How to get started?

Follow these easy steps:

- Request a free consultation: Our experts will contact you to discuss your specific needs.

- Get personalized recommendations: We’ll provide tailored advice and a no-obligation quote.

- Move forward with confidence: Once you decide, we’ll process your order and arrange delivery.

- Have global professional support: After your purchase, we make sure that you’ll have support whenever you need it.

With the ALLU D-Series, you can streamline your operations, save money, reduce environmental impact, and increase profits. Don’t wait – get your job done easier with ALLU!

Better for you, better for the environment

D-Series features

ALLU Transformer D-Series Screening Buckets are designed for all sorts of material handling jobs, from compost aeration to landscaping and construction waste treatment, not forgetting pipeline backfilling. This is a hydraulic attachment for excavators and loaders, that screens, crushes, aerates, mixes, separates, feeds and loads materials in a one-step operation.

Efficient – process materials fast and efficiently in one step

Mobile – converts your base machine into a mobile processing plant

Greener – smaller carbon footprint and reduced material transportation costs

Plug & play – simple installation to excavators and wheel loaders

Multiple configurations – change between different fragment sizes and applications

Powerful – works well even with wet materials

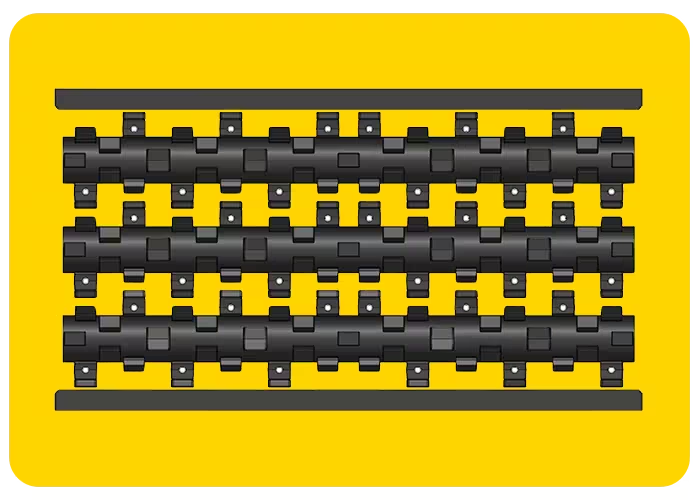

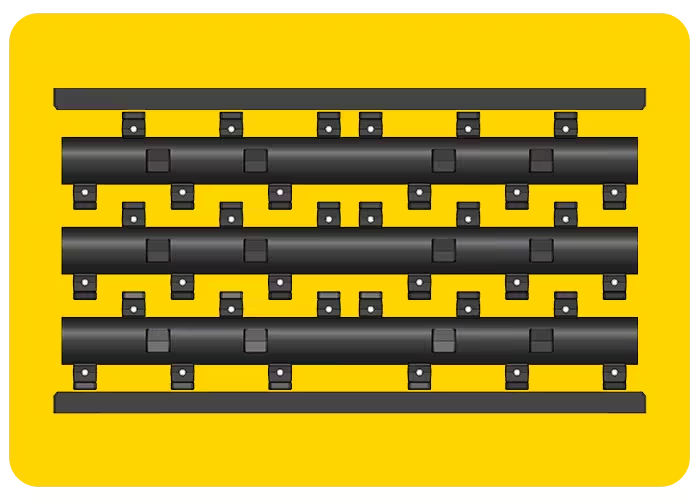

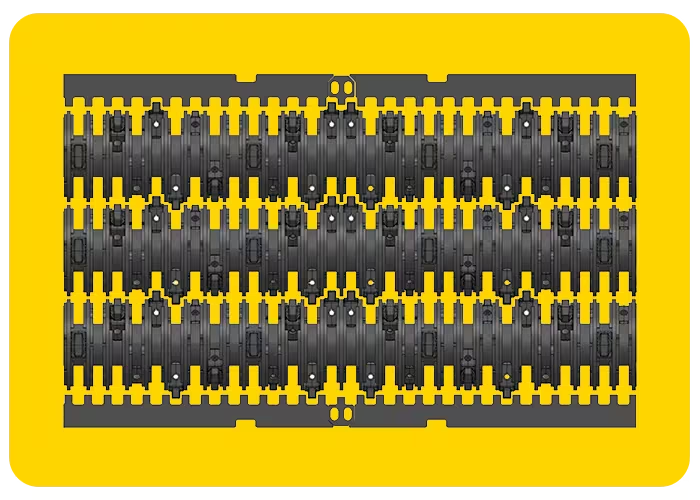

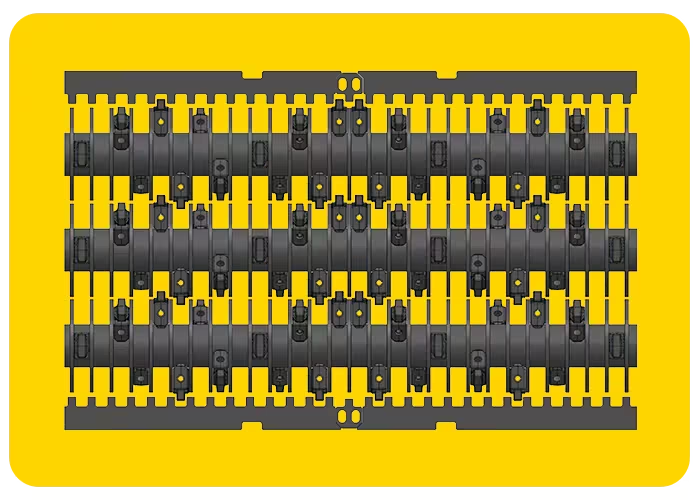

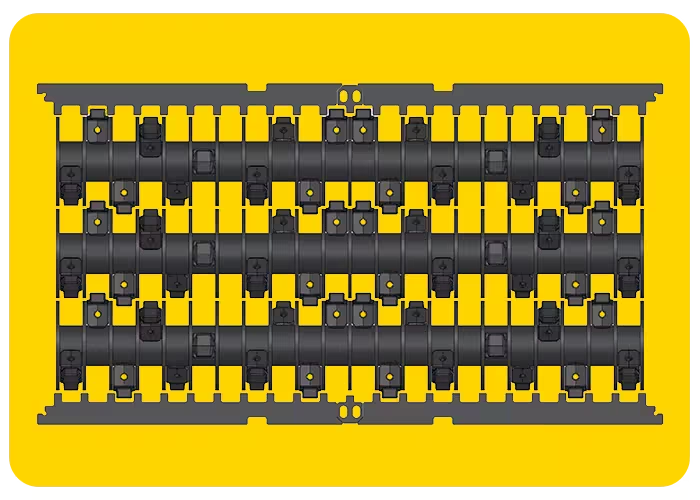

DRUMS & BLADES

MULTIPLE CONFIGURATIONS

VERSATILE PROCESSING

The ALLU Screening Buckets are designed to be used in various applications and with a multitude of base machines ranging from large excavators to small skid steers. Therefore you can have your screening bucket fitted with multiple drum and blade configurations.

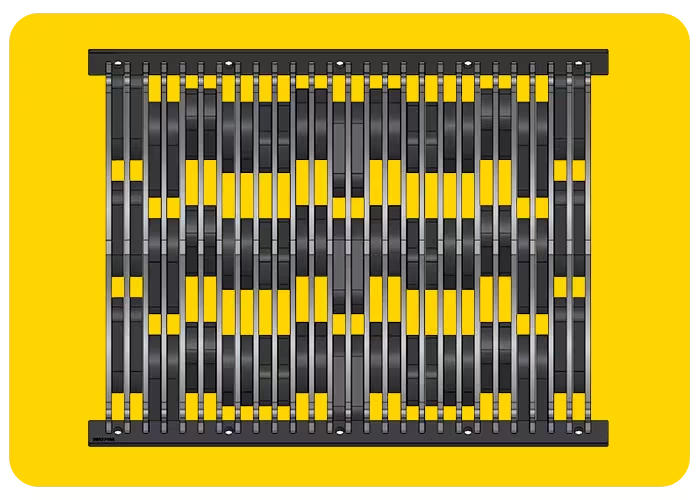

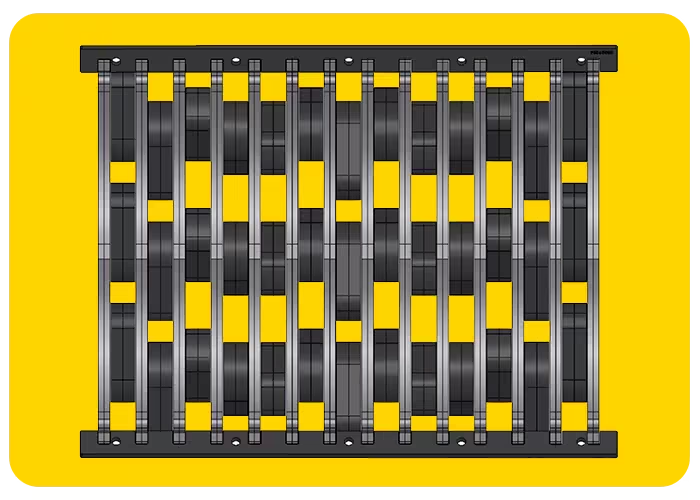

SELF-CLEANING DESIGN

The patented ALLU Top Screen Blades are the ultimate tool for screening materials like top soil, sand, and construction waste. The TS Self-Cleaning Design allows the best possible capacity even with wet materials without clogging and breakdowns.

SCREEN, CRUSH, AERATE, MIX

By changing the drum structure and blade options you can use the same screening bucket for a variety of tasks. Alternatively, you can have multiple screening buckets set up for the tasks you need. For crushing and aerating use the X-Drums, for all screening applications choose the TS drum structure. XHD can be used for mixing, screening and crushing.

VARIABLE DRUM OPTION

Selected ALLU D-Series models are available with the Variable Drum setup. The Variable Drum is a new drum structure with a rapid blade change mechanism with a 2-bolt locking system. Available drums are TS and X75.

Interested?

With the ALLU D-series Screening Crushing Bucket, you’ll ensure smoother everyday operations while converting raw materials into more valuable forms.

Don’t wait – get your job done easier with ALLU!

Main Application Areas

- Demolition

- Composting

- Construction

- Aerating

- Utility and road works

- Pipeline padding

- Solar padding

- Asphalt recycling

- Waste rock handling

- Concrete recycling

- Topsoil screening

- Waste processing

D-SERIES CASE STUDIES

ROBUST – RELIABLE – ADVANCED

ALLU Tracker

Keep your equipment safe and monitor their use with the ALLU data tracker.

- Easily mounted data tracking devices in an IP69k design. Battle-proven and tested under the harshest of circumstances.

- Monitor running hours based on motion.

- Worldwide GSM network coverage with LTE and 2G fallback. The data logging feature ensures data is stored if networks are unavailable.

- Devices can always be located with built-in GPS or network triangulation positioning.

- Manage online from anywhere, all hardware is managed online on the ALLU Data Portal.

ALLU Tracker has a long battery life of up to 5 years. Due to its small size (68 x 68 x 25 mm) and easy mounting with magnet, it doesn’t interfere with the structural integrity of the ALLU products.

Didn’t find what you were looking for?

Get to know our other Screening Bucket products, and find the perfect one for you. If you need help finding the perfect option for you, please get in touch with us and we’ll guide you.