Why Add Water When It Isn’t Necessary? A Practical Solution for Soil Stabilization in Nordic Roadworks

In the realm of construction, challenges posed by soft or unstable soils can be daunting. However, innovative techniques such as Nordic Dry Deep Soil Mixing (NDDM) offer reliable solutions without unnecessary complexity. This method demonstrates its value by improving soil stability and strength without the excessive use of water—an approach both efficient and environmentally considerate.

Project Overview: Foundation Preparation with Precision

A recent roadworks foundation project in the Nordic region highlighted the practical application of NDDM. The project scope included the construction of 12,000 soil-stabilizing columns, each reaching a depth of 10 meters (32 feet) with a diameter of 600 mm, collectively spanning an impressive total length of approximately 120 kilometers (74 miles).

Using a lime-cement mix as the binder, 40 kilograms (88 pounds) were applied per meter of each column. The outcome was a durable foundation capable of withstanding demanding load-bearing conditions.

Equipment in Action: Reliable Tools for Reliable Results

The success of the project hinged on the integration of robust equipment:

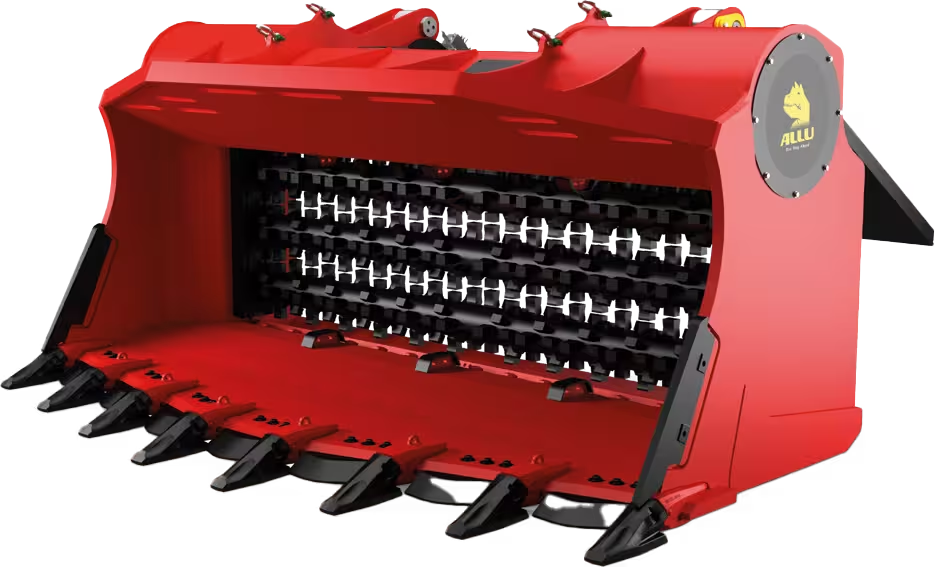

- ALLU PF 7+7 NextGen 10 Bar Pressure Feeder: Ensuring consistent and precise delivery of dry binders deep into the ground.

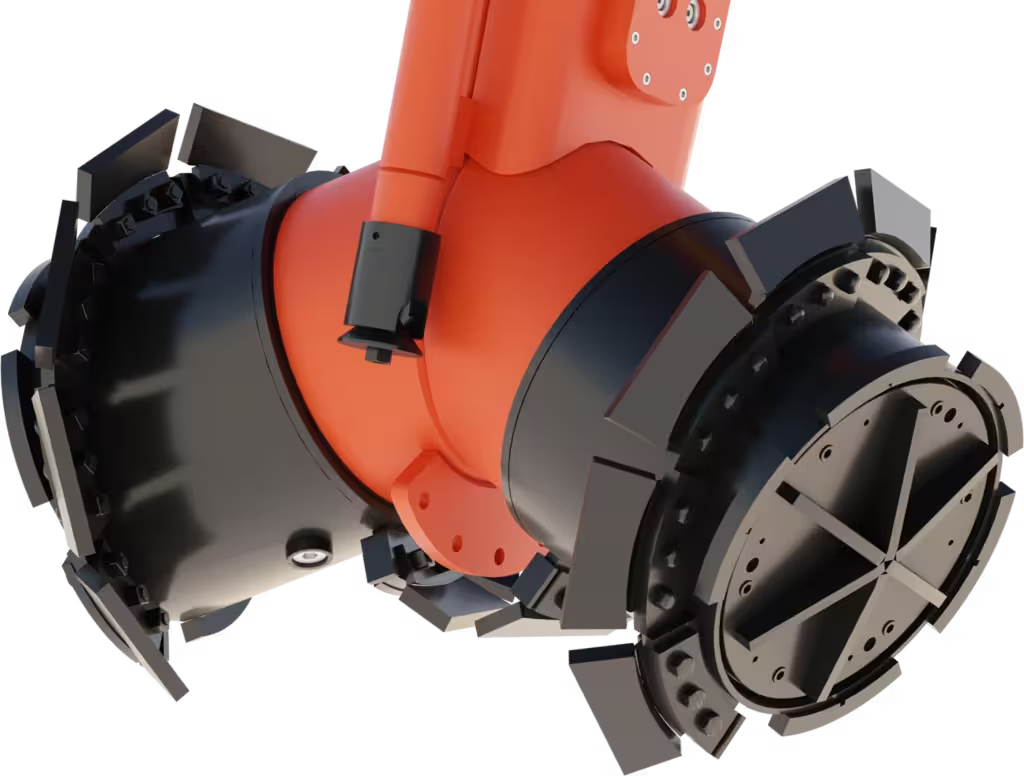

- MOVAX MSL-300 Column Stabilisation Leader: An excavator-mounted tool designed for the efficient creation of stabilization columns.

This combination provided seamless operation, even in the most demanding soil conditions, ensuring the job was completed with precision and reliability.

Why Choose Dry Over Wet Stabilization?

Nordic Dry Deep Mixing sets itself apart from traditional methods by omitting the need for added water, a factor that significantly simplifies the process. Some notable advantages include:

- Environmental Considerations

By reducing water usage, NDDM minimizes the risk of runoff and contamination, particularly in regions with high groundwater levels. This makes it a preferred choice for environmentally sensitive areas. - Enhanced Precision

Dry binders allow for controlled application, ensuring uniform strength and stability, even in soils with varying properties like clay or peat. - Faster Results

Dry binders typically achieve the desired strength more quickly than their wet counterparts, shortening project timelines and reducing waiting periods for curing. - Suitability for Difficult Conditions

In saturated or clay-rich soils, where water-based methods may fail due to dilution, NDDM excels by providing consistent results. - Reduced Complexity

With no added water, there’s no need for managing slurry or dealing with excess waste, streamlining logistics and cutting down on ancillary costs.

A Method Rooted in Practicality

The Nordic Dry Deep Mixing method isn’t just about achieving technical excellence; it’s about approaching projects with care and foresight. By avoiding the unnecessary addition of water, this method prioritizes efficiency and environmental responsibility.

For the foundation project in question, the combination of NDDM and ALLU’s PF 7+7 NextGen feeder exemplified how precision equipment and proven methods can align to create lasting infrastructure. The resulting columns are a testament to how carefully planned construction can address even the most challenging soil conditions.