Warum Wasser hinzufügen, wenn es nicht nötig ist? Eine praktische Lösung für die Bodenstabilisierung im nordischen Straßenbau

Im Bauwesen stellen weiche oder instabile Böden oft eine große Herausforderung dar. Doch innovative Verfahren wie die Dry-Deep-Mixing-Methode (DDM) bieten eine zuverlässige Lösung – ohne unnötige Komplexität. Diese Technik verbessert die Bodenstabilität und Tragfähigkeit ohne den übermäßigen Einsatz von Wasser – eine effiziente und umweltfreundliche Vorgehensweise.

Projektübersicht: Präzise Vorbereitung der Fundamentierung

Ein kürzlich durchgeführtes Straßenbauprojekt in der nordischen Region hat die praktische Anwendung von NDDM veranschaulicht. Dabei wurden 12.000 Bodenstabilisierungssäulen mit einer Tiefe von jeweils 10 Metern und einem Durchmesser von 600 mm eingebaut. Insgesamt erreichten die Säulen eine beeindruckende Gesamtlänge von rund 120 Kilometern.

Als Bindemittel wurde ein Kalk-Zement-Gemisch mit einem Gewicht von 40 kg pro Meter verwendet. Das Ergebnis: ein dauerhaft stabiles Fundament, das hohen Belastungen standhält.

Ausrüstung in Aktion: Zuverlässige Werkzeuge für zuverlässige Ergebnisse

Der Erfolg des Projekts beruhte auf der Kombination leistungsfähiger Maschinen:

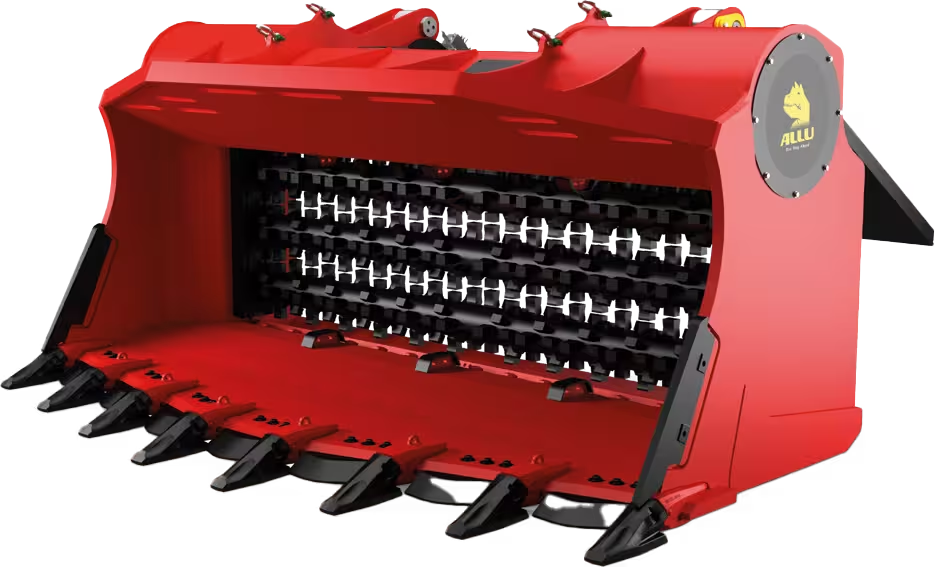

- ALLU PF 7+7 NextGen 10 Bar Pressure Feeder – sorgt für eine gleichmäßige und präzise Dosierung trockener Bindemittel in tiefere Bodenschichten.

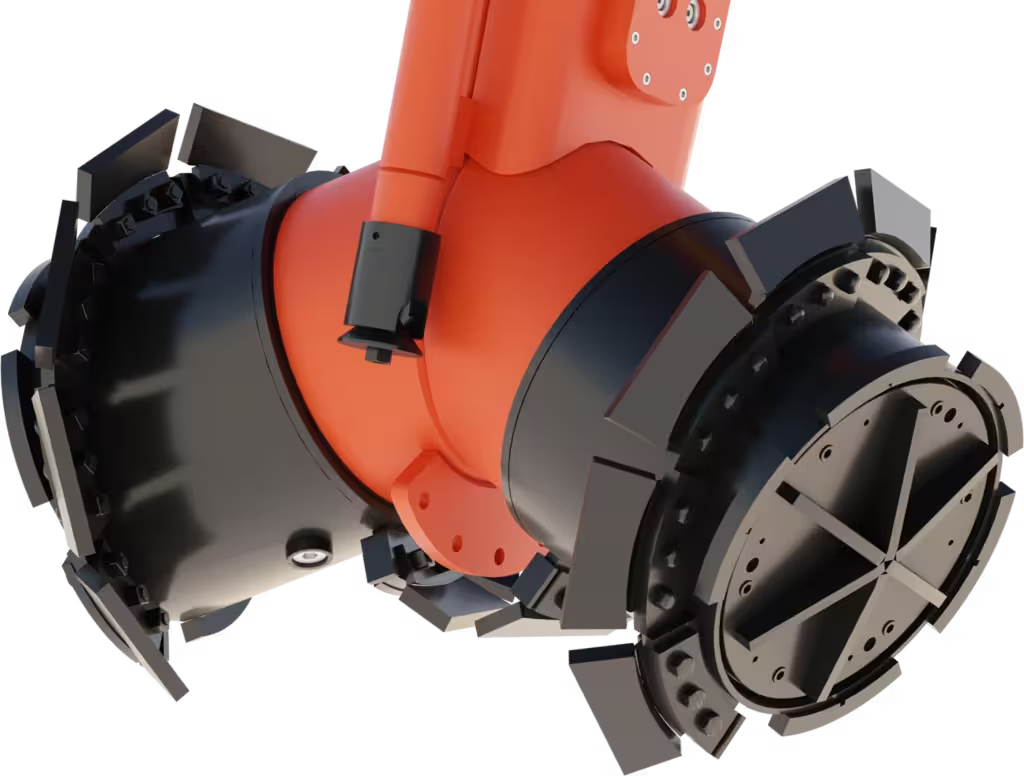

- MOVAX MSL-300 Column Stabilisation Leader – ein Baggeranbaugerät zur effizienten Herstellung von Stabilisierungssäulen.

Diese Kombination ermöglichte einen reibungslosen Betrieb auch unter schwierigsten Bodenbedingungen und stellte sicher, dass der Auftrag präzise und zuverlässig ausgeführt wurde.

Warum Trockenstabilisierung statt Nassverfahren?

Das Nordic Dry Deep Mixing unterscheidet sich von herkömmlichen Verfahren durch den Verzicht auf zusätzliches Wasser. Dies bringt zahlreiche Vorteile:

- Umweltaspekte

Durch den reduzierten Wasserverbrauch wird das Risiko von Oberflächenabfluss und Kontamination minimiert – besonders wichtig in Gebieten mit hohem Grundwasserspiegel. Damit ist das Nordic Dry Deep Mixing eine bevorzugte Wahl für ökologisch sensible Gebiete. - Höhere Präzision

Trockene Bindemittel ermöglichen eine kontrollierte Dosierung, wodurch eine gleichmäßige Festigkeit und Stabilität erreicht wird – selbst in Böden mit variierenden Eigenschaften wie Ton oder Torf. - Schnellere Ergebnisse

Trockene Bindemittel entwickeln ihre Festigkeit oft schneller als Nassverfahren, wodurch sich Projektlaufzeiten verkürzen und Wartezeiten für die Aushärtung reduziert werden. - Ideal für schwierige Bodenverhältnisse

In gesättigten oder tonreichen Böden, wo wasserbasierte Verfahren durch Verdünnung scheitern können, liefert NDDM konsistente Ergebnisse. - Weniger Komplexität

Da kein zusätzliches Wasser verwendet wird, entfällt die aufwendige Handhabung von Schlamm sowie die Entsorgung überschüssiger Materialien, was die Logistik vereinfacht und Kosten reduziert.

Ein Verfahren mit Weitblick

Das Nordic Dry Deep Mixing ist nicht nur eine technische Lösung – es steht für eine ebenso vorausschauende wie nachhaltige Bauweise. Durch den Verzicht auf unnötige Wasserzugabe ist diese Methode effizient und umweltfreundlich.

Bei dem hier beschriebenen Straßenbauprojekt zeigte die Kombination aus NDDM und dem ALLU PF 7+7 NextGen Druckförderer, wie präzise Maschinen und bewährte Verfahren zusammenwirken, um dauerhafte Infrastruktur zu schaffen. Die dabei entstandenen Stabilisierungssäulen sind ein Beweis für durchdachte Bauplanung, die selbst die schwierigsten Bodenverhältnisse meistert.