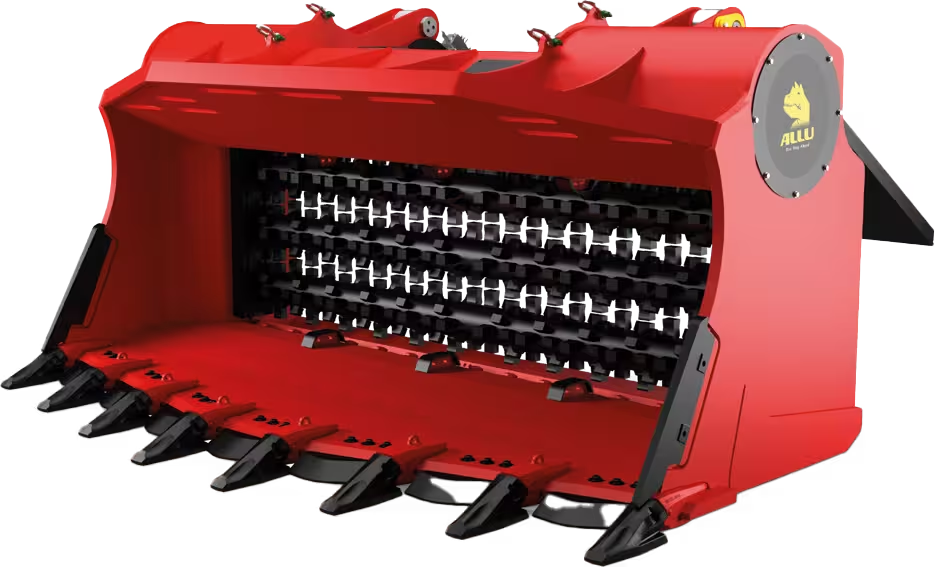

Fast drum and blade changes

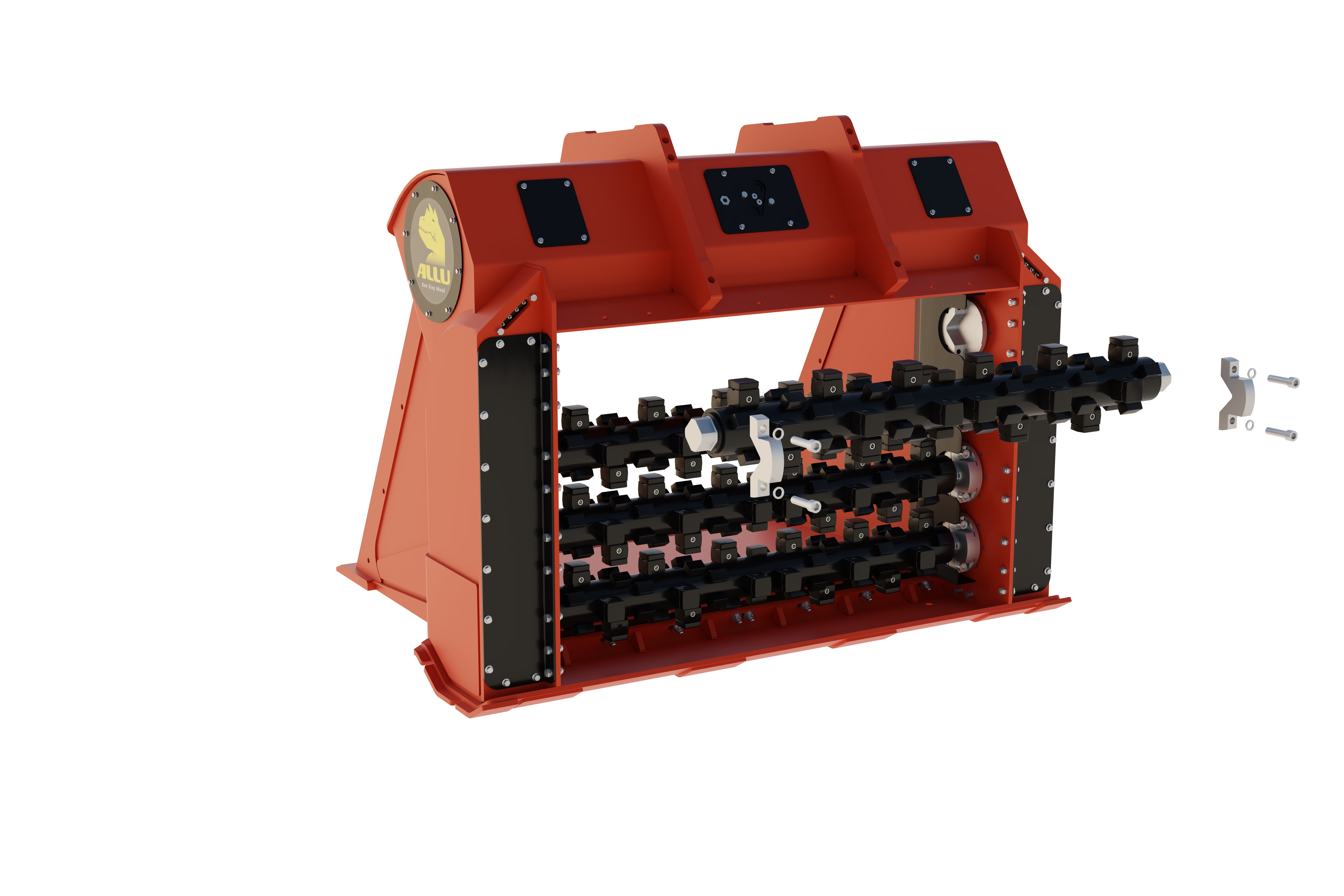

The ALLU Variable Drum is a new drum structure with a rapid blade change mechanism. Innovation is designed to streamline your operations and boost your productivity. It’s available across our DN-, DS-, and DH-Series. The VD Drum is a game-changer in material processing efficiency.

Versatility Made Simple: The Variable Drum brings flexibility to your workflow. Individual shaft removal allows for quick blade replacements or adjustments to output sizes, all within a matter of hours. This adaptability is crucial for those requiring varied operations from a single Transformer Screening bucket, enabling easy and fast modifications to meet changing job demands.

Elevate Your Productivity: Achieve superior screening performance with the Variable Drum, designed for up to a 10% increase in efficiency with a single-blade TS setup. You can get higher output with fewer screening combs and less restriction on material flow. Adjusting output sizes is straightforward, allowing for more efficient operation with less effort.

Effortless Maintenance: The Variable Drum’s innovative design simplifies maintenance tasks. Its two-bolt drum attachment system allows easy changes. Changing wear parts or modifying output sizes has never been easier or cleaner, eliminating the need to access the drive compartment and significantly reducing labor time.

BETTER FOR YOU

BETTER FOR THE ENVIRONMENT

D-Series features

ALLU Transformer D-Series Screening Buckets are designed for larger material handling jobs, from compost aeration to landscaping and construction waste treatment, not forgetting pipeline backfilling. This is a hydraulic attachment for excavators and loaders, that screens, crushes, aerates, mixes, separates, feeds and loads materials in a one-step operation.

Efficient – process materials fast and efficiently in one step

Mobile – converts your base machine into a mobile processing plant

Greener – smaller carbon footprint and reduced material transportation costs

Plug & play – simple installation to excavators and wheel loaders

Changeable blades – change between different fragment sizes and applications

Self-cleaning design – works well even with wet materials

Technical Specifications

| Excavator | 22,050 – 62,000 lbs |

| Wheel loader | 8,800 – 31,000 lbs |

| Volume | 0.7 – 0.9 cu yd |

| Oil flow | 18.4 – 31.7 gpm (TS* 25 – 42.2 gpm) |

| Weight | 2,359 – 2,668 lbs |

| Excavator | 33,000 – 62,000 lbs |

| Wheel loader | 1,5400 – 31,000 lbs |

| Volume | 1.0 – 1.3 cu yd |

| Oil flow | 18.4 – 31.7 gpm (TS* 25 – 42.2 gpm) |

| Weight | 2,932 – 3,329 lbs |

| Excavator | 22,050 – 62,000 lbs |

| Wheel loader | 13,200 – 31,000 lbs |

| Volume | 0.8 – 1.0 cu yd |

| Oil flow | 18.4 – 31.7 gpm |

| Weight | 2,535 – 2, 888 lbs |

| Excavator | 35,300 – 62, 000 lbs |

| Wheel loader | 15,400 – 31,000 lbs |

| Volume | 1.0 – 1.3 cu yd |

| Oil flow | 25 – 42.2 gpm (TS* 31.7 – 52.8 gpm) |

| Weight | 2,932 – 3,373 lbs |

| Excavator | 44,100 – 62,000 lbs |

| Wheel loader | 15,400 – 31,000 lbs |

| Volume | 1.5 – 2.0 cu yd |

| Oil flow | 25 – 42.2 gpm (TS* 31.7 – 52.8 gpm) |

| Weight | 3,814 – 4,255 lbs |

| Excavator | 35,300-77,000 lbs |

| Wheel loader | 17,600-48,500 lbs |

| Volume | 1.1 – 1.4 cu yd |

| Oil flow | 25 – 42.2 gpm (TS* 31.7 – 52.8 gpm) |

| Weight | 3,461 – 3,792 lbs |

| Excavator | 44,100 – 77,000 lbs |

| Wheel loader | 22,100 – 48,500 lbs |

| Volume | 1.6 – 2.1 cu yd |

| Oil flow | 25 – 42.2 gpm (TS* 31.7 – 52.8 gpm) |

| Weight | 4,233 – 4,784 lbs |

| Excavator | 53,000 – 77,000 lbs |

| Wheel loader | 26,500 – 48,500 lbs |

| Volume | 2.1 – 2.8 cu yd |

| Oil flow | 31.7 – 52.8 gpm (TS* 36.9 – 62.0 gpm) |

| Weight | 5,181 – 6,019 lbs |

| Excavator | 53,000 – 77,000 lbs |

| Wheel loader | 26,500 – 48,500 lbs |

| Volume | 2.4 – 3.1 cu yd |

| Oil flow | 31.7 – 52.8 gpm (TS* 36.9 – 62.0 gpm) |

| Weight | 4,938 – 5,710 lbs |

| Excavator | 66,100 – 77,000 lbs |

| Wheel loader | 31,000 – 48,500 lbs |

| Volume | 3.1 – 4.2 cu yd |

| Oil flow | 50.1 – 83.2 gpm |

| Weight | 6,570 – 7,584 lbs |

| Excavator | 39,700 – 94,000 lbs |

| Wheel loader | 17,600 – 66,100 lbs |

| Volume | 1.1 – 1.4 cu yd |

| Oil flow | 36.9 – 62.0 gpm (TS* 50.1 – 83.2 gpm) |

| Weight | 4,167 – 4,586 lbs |

| Excavator | 48,500 – 94,000 lbs |

| Wheel loader | 22,100 – 66,100 lbs |

| Volume | 1.6 – 2.1 cu yd |

| Oil flow | 36.9 – 62.0 gpm (TS* 50.1 – 83.2 gpm) |

| Weight | 5,137 – 5,666 lbs |

| Excavator | 57,000 – 94,000 lbs |

| Wheel loader | 31,000 – 66,100 lbs |

| Volume | 2.2 – 2.8 cu yd |

| Oil flow | 36.9 – 62.0 gpm (TS* 50.1 – 83.2 gpm) |

| Weight | 6,327 – 6,989 lbs |

| Excavator | 48,500 – 94,000 lbs |

| Wheel loader | 22,100 – 66,100 lbs |

| Volume | 1.6 – 2.1 cu yd |

| Oil flow | 36.9 – 62.0 gpm (TS* 50.1 – 83.2 gpm) |

| Weight | 4,938 – 5,357 lbs |

| Excavator | 59,500 – 94,000 lbs |

| Wheel loader | 31,000 – 66,100 lbs |

| Volume | 2.4 – 3.2 cu yd |

| Oil flow | 36.9 – 62.0 gpm (TS* 50.1 – 83.2 gpm) |

| Weight | 6,019 – 6,724 lbs |

| Excavator | 70,600 – 94,000 lbs |

| Wheel loader | 35,300 – 66,100 lbs |

| Volume | 3.2 – 4.3 cu yd |

| Oil flow | 50.1 – 83.2 gpm (TS* 50.1 – 83.2 gpm) |

| Weight | 7,430 – 8,311 lbs |

| Excavator | 79,500 – 94,000 lbs |

| Wheel loader | 40,000 – 61,000 lbs |

| Volume | 3.9 – 5.4 cu yd |

| Oil flow | 63.4 – 105.6 gpm (TS* 63.4 – 105.6 gpm) |

| Weight | 8,510 – 9,259 lbs |

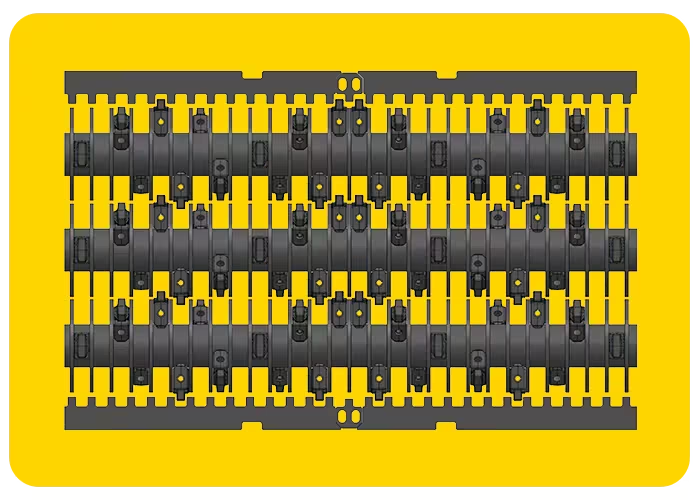

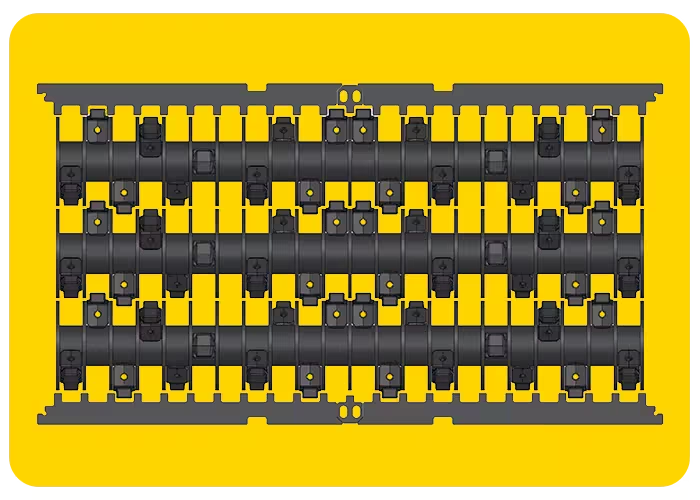

DRUMS & BLADES

MULTIPLE CONFIGURATIONS

VERSATILE PROCESSING

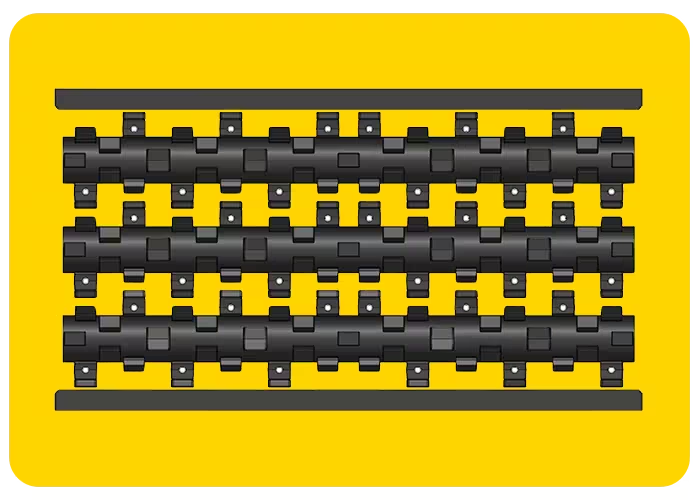

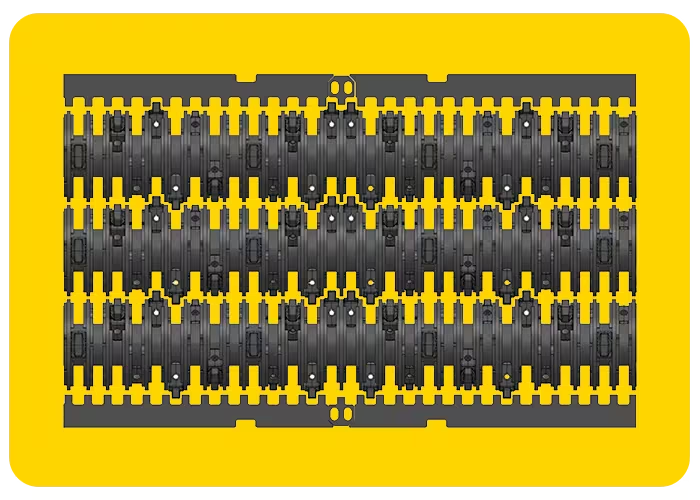

The ALLU Screening Buckets are designed to be used in various applications and with a multitude of base machines ranging from large excavators to small skid steers. Therefore you can have your screening bucket fitted with multiple drum and blade configurations.

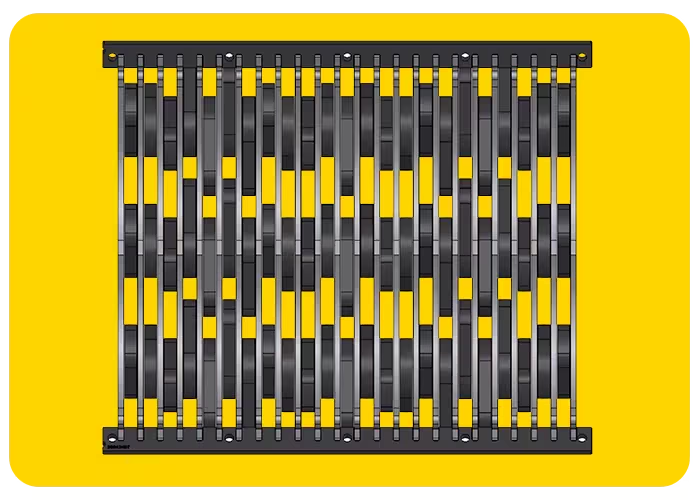

SELF-CLEANING DESIGN

The patented ALLU Top Screen Blades are the ultimate tool for screening materials like top soil, sand, and construction waste. The TS Self-Cleaning Design allows the best possible capacity even with wet materials without clogging and breakdowns.

SCREEN, CRUSH, AERATE, MIX

By changing the drum structure and blade options you can use the same screening bucket for a variety of tasks. Alternatively, you can have multiple screening buckets set up for the tasks you need. For crushing and aerating use the X-Drums, for all screening applications choose the TS drum structure, use XHD for screening, mixing and crushing.

Speak to

a specialist

With the ALLU Variable Drum, you’ll enjoy enhanced flexibility, increased efficiency, faster project completion, lower operational costs, and reduced environmental impact.

Don’t wait – make your job smoother with ALLU!

Main Application Areas

- Demolition

- Excavation

- Construction

- Utility and Road works

- Waste Recycling

- Asphalt Recycling

- Waste Rock Handling at quarries

- Concrete Pipe Industry

- Topsoil screening

CUSTOMER STORIES

ROBUST – RELIABLE – ADVANCED

ALLU Tracker

Keep your equipment safe and monitor their use with the ALLU data tracker.

- Easily mounted data tracking devices in an IP69k design. Battle-proven and tested under the harshest of circumstances.

- Monitor running hours based on motion.

- Worldwide GSM network coverage with LTE and 2G fallback. The data logging feature ensures data is stored if networks are unavailable.

- Devices can always be located with built-in GPS or network triangulation positioning.

- Manage online from anywhere, all hardware is managed online on the ALLU Data Portal.

ALLU Tracker has a long battery life of up to 5 years. Due to its small size (68 x 68 x 25 mm) and easy mounting with magnet, it doesn’t interfere with the structural integrity of the ALLU products.

Didn’t find what you were looking for?

Get to know our other Screening Bucket products, and find the perfect one for you. If you need help finding the perfect option for you, please get in touch with us and we’ll guide you.