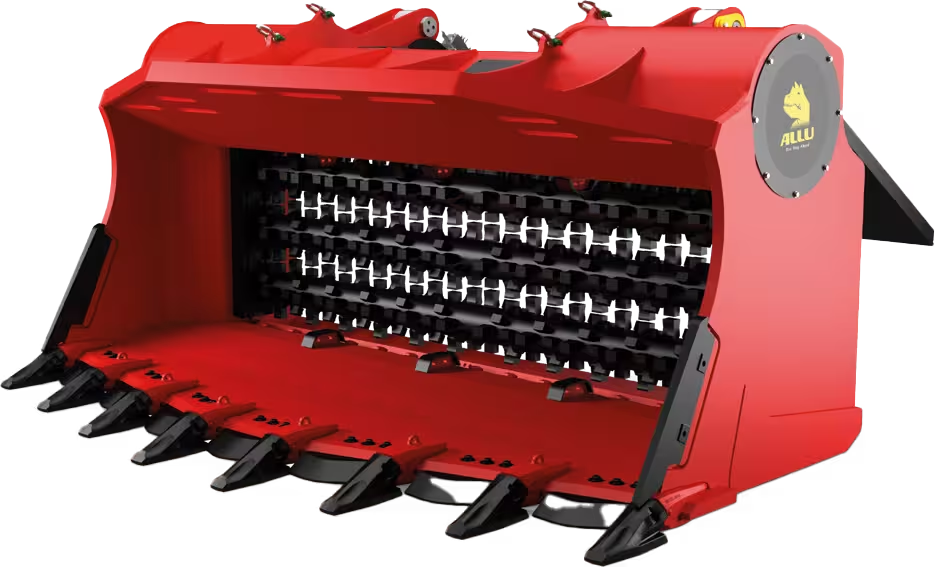

Crushing large volumes of limestone effectively calls for equipment that guarantees speed and accuracy. In the demanding environment of Oman, a customer chose the ALLU M 3-25 screening bucket, mounted on a Hitachi 90-tonne excavator, to handle limestone boulders with precision and speed. This solution not only eliminated the need for a conventional crusher but also transformed operations into a one-step process that saved time, reduced costs, and minimized environmental impact.

The Challenge: Crushing Limestone Boulders for Road Construction

The customer’s challenge was to break down large limestone boulders ranging from 0 to 300 mm into smaller, manageable pieces, specifically between 0 and 90 mm. The material needed to be prepared as sub-base for the internal road construction at the Royal Oman Police Headquarters. Conventionally, this would require multiple machines and permits to set up a traditional crusher on-site, causing additional costs and logistical complexities.

The ALLU Solution: One-Step Operation with M 3-25 Screening Bucket

Choosing the ALLU M 3-25 X75 over a traditional crusher setup, the customer valued its capacity to condense several stages of the process into one seamless operation. Mounted on a Hitachi 90-tonne excavator, the ALLU screening bucket ensured a smooth, efficient workflow throughout the operation. The excavator simply picked up the boulders, crushed them to the desired size, and loaded them directly onto trucks for transport.

This one-step operation not only saved the customer significant time and reduced the need for additional equipment but also minimized environmental impact by reducing fuel consumption and the overall number of machines on-site. The crushed material was perfectly sized for the sub-base application, helping ensure that the project was completed efficiently and on time.

Key Benefits of the ALLU Screening Bucket:

- Cost-Efficient Versatility: By choosing this screening bucket, the customer bypassed the permits and costs of a conventional crusher, while handling a large-scale operation with one versatile attachment.

- One-Step Process: The ALLU screening bucket streamlined the operation into a single process, from picking up material to crushing and loading it onto trucks.

- Sustainable Precision: Fewer machines on-site meant reduced emissions and fuel consumption, while the bucket’s precision ensured perfectly sized material for sub-base road construction.

Why ALLU Stands Out for Material Processing

ALLU’s innovative screening and crushing buckets, like the M 3-25, are engineered for large-scale operations in industries such as construction and mining. Designed for efficiency, they reduce the need for multiple machines while boosting productivity and streamlining job site processes. Whether you’re crushing limestone, screening soil, or preparing materials for road construction, ALLU delivers reliable, durable equipment that can handle even the toughest materials, transforming how you approach material handling.

Learn more about the ALLU M 3-25 bucket and how it can help streamline your next project. Visit our website or contact us today to explore the full range of ALLU solutions.