The ALLU Asphalt Screening bucket is designed specifically for cold-milled and reclaimed asphalt (RAP). It crushes clumps, screens fine material, and separates oversized particles – all in a single pass. Thanks to its innovative hybrid blade setup, you get just the right amount of crushing power combined with efficient screening.

By handling the majority of the material directly with the ALLU bucket, you drastically reduce the need for expensive impact crushers, cutting down on fuel consumption, wear part replacements, and operating hours. This results in significant savings in both time and money, making the process not only more efficient but far more profitable.

Whether you’re processing 100 or 250 tons per hour, ALLU helps you optimize your recycled asphalt handling – keeping your fleet productive and your bottom line strong.

Efficiency Meets Profitability

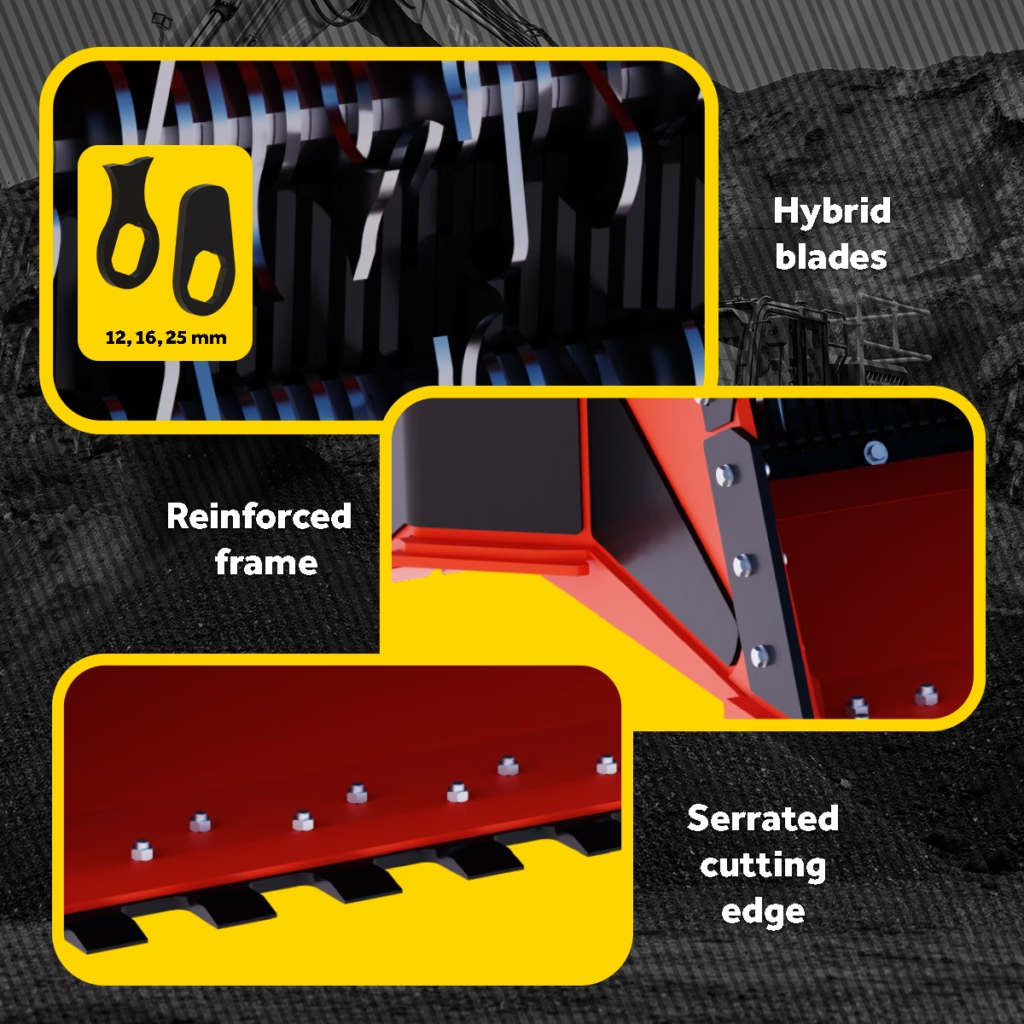

The Asphalt Bucket utilizes a hybrid blade configuration – a mix of screening and crushing blades – to fine-tune performance and achieve consistently high-quality end products. This combination allows operators to process cold-milled asphalt directly at the source without additional crushing equipment.

With nominal screen sizes of 12, 16, and 25 mm, the bucket can produce over 95% of finished material below target size, drastically reducing reprocessing needs.

Key features include:

- One-Step Operation: Crushes and screens simultaneously, eliminating the need for separate pre-crushing or secondary equipment.

- Lower Total Costs: Reduces reliance on mobile impact crushers, cutting fuel consumption, wear part expenses, and overall ton-per-cost rates.

- Proven Throughput: Models deliver up to 250 tons per hour, with rapid drum change-outs thanks to the Variable Drum technology.

Asphalt Bucket Models

The DHA-Series consists of 4 models: DHA 3-17, DHA 3-23, DHA 4-17, and DHA 4-23. The first number in the model name is the number of drums, and the last number is the width of the bucket e.g. 17 means 1700 mm.

DHA 3-23

DHA 4-17

Technical Specifications

| Excavator | 25 – 45 t |

| Wheel loader | 15 – 20 t |

| Volume | 1.43 m3 |

| Oil flow | 190 – 315 l/min |

| Weight | 2,700 – 2,800 kg |

| Excavator | 30 – 45 t |

| Wheel loader | 15 – 25 t |

| Volume | 1.91 m3 |

| Oil flow | 190 – 315 l/min |

| Weight | 3,350 – 3,450 kg |

| Excavator | 30 – 45 t |

| Wheel loader | 15 – 25 t |

| Volume | 2.14 m3 |

| Oil flow | 190 – 315 l/min |

| Weight | 3,250 – 3,350 kg |

| Excavator | 35 – 45 t |

| Wheel loader | 20 – 30 t |

| Volume | 2.85 m3 |

| Oil flow | 240 – 400 l/min |

| Weight | 3,800 – 3,900 kg |

This Contractor Changed How They Process Asphalt

- Transforming RAP on-site with ALLU buckets

- Processing lumpy material that clogs conventional screeners

- Adapt to any job size – from small contracts to major projects

Special Product Features

The ALLU Asphalt bucket is engineered to deliver high productivity and long-lasting durability in recycled asphalt processing. At the heart of its performance is the hybrid blade setup, which combines TS standard screening blades with TS Axe crushing blades. This configuration allows you to efficiently screen fines while crushing oversized lumps in a single pass, maximizing throughput and minimizing the need for additional equipment.

Supporting this performance is a reinforced frame structure that withstands impacts and abrasion typical in asphalt recycling applications. The frame is built for longevity and stability. Up front, the serrated bolt-on cutting edge improves material penetration and protects the bucket’s lower structure from wear, helping to extend the service life of your investment.

The bucket has the Variable Drum structure, which allows for easy blade and drum configuration changes without opening the chainbox. This design simplifies maintenance and reduces downtime.

Interested?

With the ALLU Asphalt Screening Bucket, you’ll ensure smoother everyday operations while converting raw materials into more valuable forms.

Don’t wait – get your job done easier with ALLU!

Virhe: Yhteydenottolomaketta ei löytynyt.

How to get started?

Follow these easy steps:

- Request a free consultation: Our experts will contact you to discuss your specific needs.

- Get personalized recommendations: We’ll provide tailored advice and a no-obligation quote.

- Move forward with confidence: Once you decide, we’ll process your order and arrange delivery.

- Have global professional support: After your purchase, we make sure that you’ll have support whenever you need it.

With the ALLU DHA-Series, you can streamline your operations, save money, reduce environmental impact, and increase profits. Don’t wait – get your job done easier with ALLU!

Asphalt Bucket features

The ALLU Asphalt Bucket is available in several sizes for 25–45 t excavators and 15–30 t wheel loaders. Its robust design includes a serrated cutting edge and reinforced frame, tailored for aggressive asphalt processing. Whether it’s pre-crushed demolition asphalt or compacted cold-milled material, the ALLU solution is engineered for reliability, mobility, and productivity – even in tight or urban work sites.

Efficient – process materials fast and efficiently in one step

Mobile – converts your base machine into a mobile processing plant

Greener – smaller carbon footprint and reduced material transportation costs

Plug & play – simple installation to excavators and wheel loaders

Easy maintenance – change the wear part easily due to the Variable Drum setup

Powerful – works well even with condensed and lumpy materials

ROBUST – RELIABLE – ADVANCED

ALLU Tracker

Keep your equipment safe and monitor their use with the ALLU data tracker.

- Easily mounted data tracking devices in an IP69k design. Battle-proven and tested under the harshest of circumstances.

- Monitor running hours based on motion.

- Worldwide GSM network coverage with LTE and 2G fallback. The data logging feature ensures data is stored if networks are unavailable.

- Devices can always be located with built-in GPS or network triangulation positioning.

- Manage online from anywhere, all hardware is managed online on the ALLU Data Portal.

ALLU Tracker has a long battery life of up to 5 years. Due to its small size (68 x 68 x 25 mm) and easy mounting with magnet, it doesn’t interfere with the structural integrity of the ALLU products.

Didn’t find what you were looking for?

Get to know our other Screening Bucket products, and find the perfect one for you. If you need help finding the perfect option for you, please get in touch with us and we’ll guide you.