Allu announced that CBS Wearparts A/S is its new distributor in Denmark. The company will not only be supplying a comprehensive range of Allu Transformer and Processor attachments, but will also be providing full aftermarket care, spare parts and dedicated customer service.

Based Glumsø/Denmark, CBS Wearparts A/S prides itself on delivering the best and most innovative solutions to its clients, partnering with them to understand their needs, culture and business aspirations. This understanding allows the company to provide exceptional service and advanced solutions to meet any challenge using world-class products.

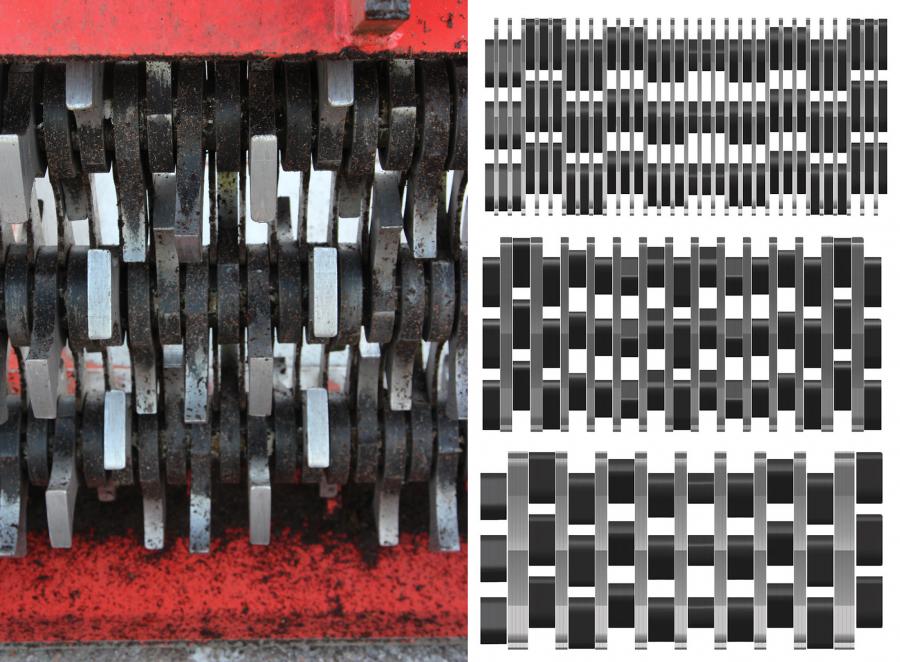

Although a relatively recently formed company (2009), CBS Wearparts A/S’s is well known to the Danish construction industry with its special focus on servicing the aftermarket requirements for crushing and screening equipment. Its product ranges includes a large selection of wear and spare parts for crushers, screens, conveyors and wear parts for loaders, as well as providing renovation services of crushers and screens.

As part of CBS Wearparts A/S’s drive to provide its customers with state of the art solutions and products, company managing director Claus Buch, was quick to spot the potential of the Allu ranges of Transformers and Processors. This has directly led to the company being appointed Allu’s dealer in Denmark, with the appointment of such a professional and experienced industry distributor reinforcing Allu’s commitment in providing even greater levels of customer focus. It also further enhances locally focused customer support, whilst at the same time enabling customers to benefit from dealing with a truly global company.

In practical terms this means that as well as CBS Wearparts A/S providing ‘point of contact’ customer support, when the situation requires it, the company will be able to call on round the clock assistance from Allu’s Finland based technical support department. This will further enable customers to benefit from the specialised advice and assistance that has made Allu the world leading supplier of material processing attachments: namely the Transformer and Processor series.

Of Allu’s appointment of CBS Wearparts A/S, Marjut Lindroos, group marketing manager states: “We are sure that the combination of Allu equipment and global aftermarket support, together with the local knowledge and industry expertise of CBS Wearparts A/S, will enable Allu customers throughout Denmark to benefit from a winning combination.”

New distributor for Allu in Denmark

Based Glumsø/Denmark, CBS Wearparts A/S prides itself on delivering the best and most innovative solutions to its clients, partnering with them to understand their needs, culture and business aspirations. This understanding allows the company to provide exceptional service and advanced solutions to meet any challenge using world-class products.

Although a relatively recently formed company (2009), CBS Wearparts A/S’s is well known to the Danish construction industry with its special focus on servicing the aftermarket requirements for crushing and screening equipment. Its product ranges includes a large selection of wear and spare parts for crushers, screens, conveyors and wear parts for loaders, as well as providing renovation services of crushers and screens.

As part of CBS Wearparts A/S’s drive to provide its customers with state of the art solutions and products, company managing director Claus Buch, was quick to spot the potential of the Allu ranges of Transformers and Processors. This has directly led to the company being appointed Allu’s dealer in Denmark, with the appointment of such a professional and experienced industry distributor reinforcing Allu’s commitment in providing even greater levels of customer focus. It also further enhances locally focused customer support, whilst at the same time enabling customers to benefit from dealing with a truly global company.

In practical terms this means that as well as CBS Wearparts A/S providing ‘point of contact’ customer support, when the situation requires it, the company will be able to call on round the clock assistance from Allu’s Finland based technical support department. This will further enable customers to benefit from the specialised advice and assistance that has made Allu the world leading supplier of material processing attachments: namely the Transformer and Processor series.

Of Allu’s appointment of CBS Wearparts A/S, Marjut Lindroos, group marketing manager states: “We are sure that the combination of Allu equipment and global aftermarket support, together with the local knowledge and industry expertise of CBS Wearparts A/S, will enable Allu customers throughout Denmark to benefit from a winning combination.”